HYDRAULIC SYSTEM EXAMPLES

It can be complex to set up a Modular Hydraulics System, and so on this page we provide two examples to help you. These samples cover a simple aircraft (like the DA62) and a complex aircraft (like the Boeing 737), and provides both a visual schematic for the systems being created, and the resulting CFG settings.

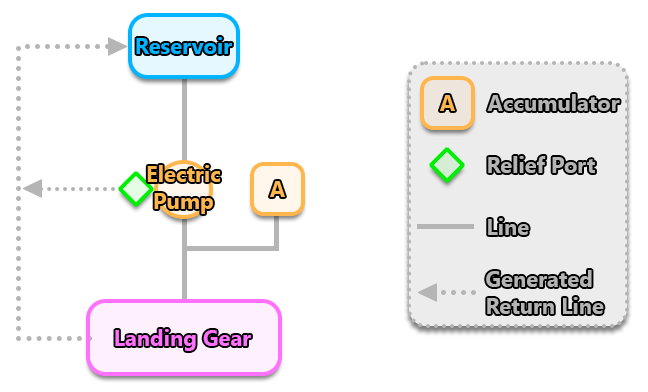

Simple Aircraft

The hydraulics system for small aircraft is a very simple one, as it only has a single actuator for the landing gear. For this actuator to work it requires the actuator itself as well as a single reservoir and an automatic electric pump provide the actuator with pressurized fluid, along with an accumulator (which allows the pilot to extend the landing gear even if the pump fails). The image below shows the schematic for the DA62 hydraulic system:

The CFG file contents for the components in this system would look like this:

[HYDRAULICS_SYSTEM_EX1]

Version = 1

Reservoir.1 = Name:Tank #Maxcapacity:10 #WearAndTearCollision:GlobalDamage

Pump.1 = Name:ElectricPump #Type:Electric #Normalpressure:2000 #Nominaldisplacement:600 #Circuit:HydraulicPump #Mode:Auto #WearAndTearCollision:GlobalDamage

Accumulator.1 = Name:Accumulator #Normalpressure:2000 #Initialpressure:1700 #Capacity:500 #WearAndTearCollision:GlobalDamage

Actuator.1 = Name:LandingGear #Fluidvolume:300 #Minimalpressure:1300 #Type:LandingGear #WearAndTearCollision:GlobalDamage

Line.1 = Name:TankToPump #Inputs:Tank #Outputs:ElectricPump #WearAndTearCollision:GlobalDamage

Line.2 = Name:PumpToLdgGear #Inputs:ElectricPump #Outputs:LandingGear #Accumulator:Accumulator #WearAndTearCollision:GlobalDamage

In this simple system, the accumulator can hold 500ml of hydraulic fluid at pump pressure, and the actuator consumes 100ml/s. This means that the accumulator can sustain the actuator for 5 seconds, but as it depletes its pressure will decrease towards its pre-charged pressure, and so it may fall below the minimal pressure of the actuator if not set correctly.

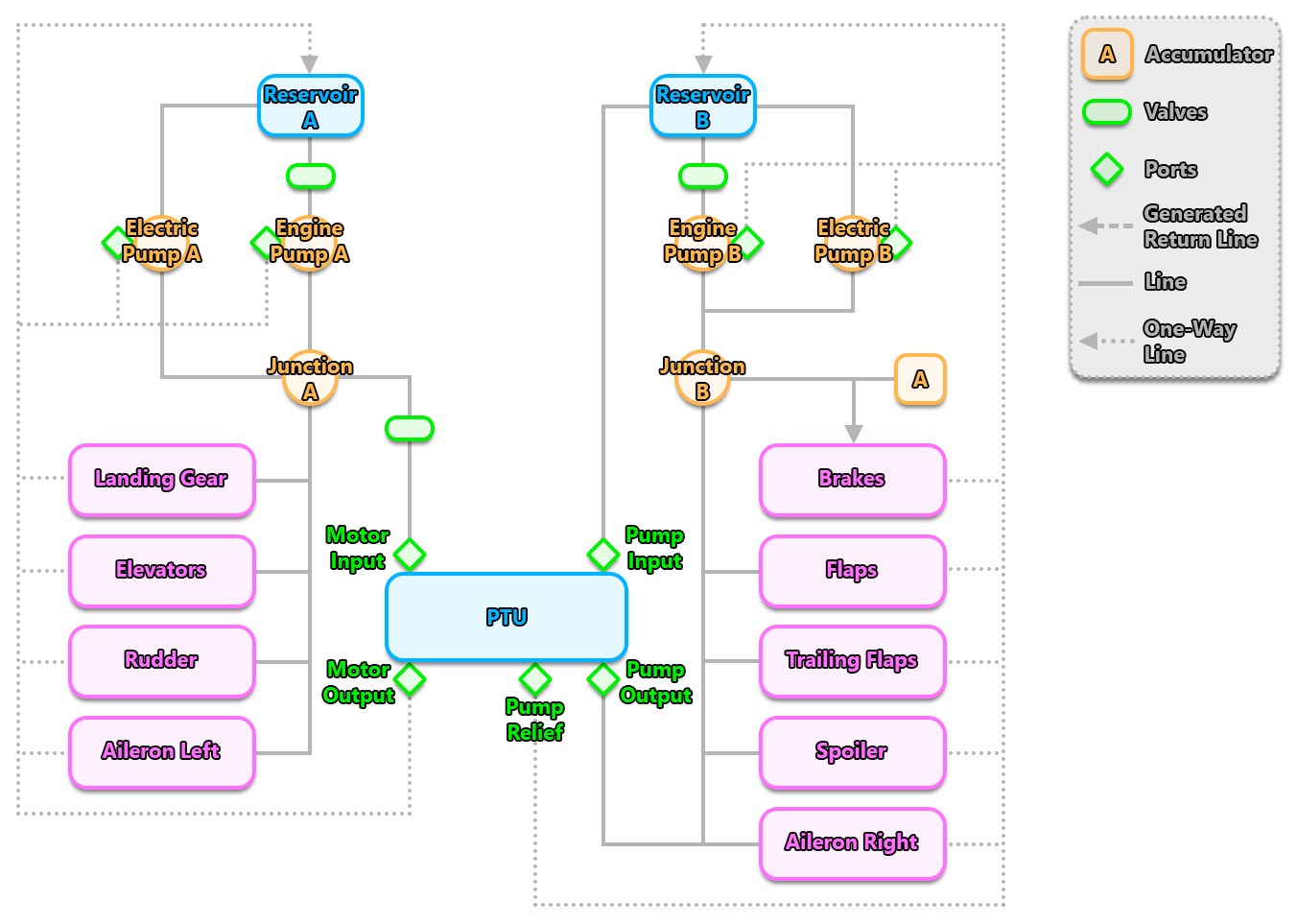

Complex Aircraft

The hydraulics system of a complex aircraft - like an airliner - is a more complex setup than the one used by the simple aircraft shown above. It has two separate hydraulics systems which are connected via a non-reversible PTU. The PTU itself is the most complex of the hydraulic components as it has multiple ports to deal with the various input and output lines. Notice that this one does not use the Motor Relief port. If it was reversible then this would be required as well. The way this system is setup means that the "A" system can provide the "B" system with hydraulic power if necessary. It is also worth noting that the number of hydraulic pumps has been doubled for the complex aircraft, as each system has an electric pump and an engine driven pump. This provides redundancy to the system, so that having a failure on any one of the pumps will not cause a catastrophic system failure.

The CFG file contents for the components in this system would look like this:

[HYDRAULICS_SYSTEM_EX1]

Version = 1

Reservoir.1 = Name:TANKA #MaxCapacity:10

Reservoir.2 = Name:TANKB #MaxCapacity:10

Valve.1 = Name:ValveSO_A #Type:ShutOff #Circuit:C_HYDRAULIC

Valve.2 = Name:ValveSO_B #Type:ShutOff #Circuit:C_HYDRAULIC

Valve.3 = Name:ValvePTU #Type:ShutOff #Index:3

Pump.1 = Name:Pump_ENG_1 #NormalPressure:3000 #NominalDisplacement:2400 #Type:EngineDriven #Index:1

Pump.2 = Name:Pump_ENG_2 #NormalPressure:3000 #NominalDisplacement:2400 #Type:EngineDriven #Index:2

Pump.3 = Name:Pump_ELEC_1 #NormalPressure:3000 #NominalDisplacement:800 #Type:Electric #Circuit:C_Hyd_PUMP_1

Pump.4 = Name:Pump_ELEC_2 #NormalPressure:3000 #NominalDisplacement:800 #Type:Electric #Circuit:C_Hyd_PUMP_2

Accumulator.1 = Name:AccumulatorBrakes #NormalPressure:3000 #InitialPressure:1080 #Capacity:3

Actuator.1 = Name:Rudder #MinimalPressure:1500 #FluidVolume:400 #Type:Rudder

Actuator.2 = Name:Flaps #MinimalPressure:1500 #FluidVolume:400 #Type:Flaps#Index:1

Actuator.3 = Name:Brakes #MinimalPressure:1000 #FluidVolume:400 #Type:Brakes

Actuator.4 = Name:LandingGear #MinimalPressure:1500 #FluidVolume:400 #Type:LandingGear

Actuator.5 = Name:Spoilers #MinimalPressure:1500 #FluidVolume:400 #Type:Spoilers

Actuator.6 = Name:Elevator #MinimalPressure:1500 #FluidVolume:400 #Type:Elevator

Actuator.7 = Name:AileronsL #MinimalPressure:1500 #FluidVolume:400 #Type:LeftAilerons

Actuator.8 = Name:AileronsR #MinimalPressure:1500 #FluidVolume:400 #Type:RightAilerons

Actuator.9 = Name:FlapsTrail #MinimalPressure:1500 #FluidVolume:400 #Type:Flap #Index:2

Junction.1 = Name:JunctionA

Junction.2 = Name:JunctionB

PTU.1 = Name:PTU #NormalPressure:3000 #NominalDisplacement:1200

Line.1 = Name:TankAToPumpEng #Inputs:TANKA #Outputs:Pump_ENG_1 #Valves:ValveSO_A

Line.2 = Name:TankAToPumpElec #Inputs:TANKA#Outputs:Pump_ELEC_1

Line.3 = Name:PumpsToJunctionA #Inputs:Pump_ENG_1,Pump_ELEC_1 #Outputs:JunctionA

Line.4 = Name:JunctionAToActuators #Inputs:JunctionA #Outputs:LandingGear,Elevator,Rudder,AileronsL

Line.5 = Name:JunctionAToPTUMotor #Inputs:JunctionA #Outputs:PTU.MotorInput #Valves:ValvePTU

Line.6 = Name:TankBToPumpEng #Inputs:TankB #Outputs:Pump_ENG_2 #Valves:ValveSO_B

Line.7 = Name:TankBToPumpElec_PTU #Inputs:TANKB #Outputs:Pump_ELEC_2,PTU.PumpInput

Line.8 = Name:PumpsToPTUActuatorsB #Inputs:PTU.PumpOutput, Pump_ENG_2, Pump_ELEC_2 #Outputs:Flaps, Spoilers, AileronsR, FlapsTrail, JunctionB

Line.9 = Name:JunctionBToBrakes #Inputs:JunctionB #Outputs:Brakes #Accumulator:AccumulatorBrakes #NonReturn