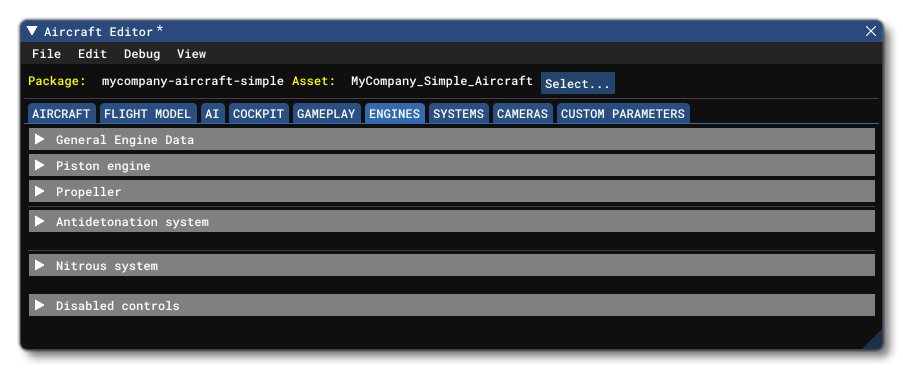

THE ENGINES TAB

This tab is used to define most of the properties associated with the aircraft engine or engines. This tab does not show all of the available properties for engines, since many of them actually depend on the type of engine that the aircraft has. For example, if you set the type as Turbo Prop, you will not see the "Piston Engine" sections any more, but you will see the "Turbine Engine Data" and "TurboProp Engine" sections. This page of the documentation lists all available parameters, but will indicate when these are optional and what factors they depend on when appropriate.

This tab is used to define most of the properties associated with the aircraft engine or engines. This tab does not show all of the available properties for engines, since many of them actually depend on the type of engine that the aircraft has. For example, if you set the type as Turbo Prop, you will not see the "Piston Engine" sections any more, but you will see the "Turbine Engine Data" and "TurboProp Engine" sections. This page of the documentation lists all available parameters, but will indicate when these are optional and what factors they depend on when appropriate.

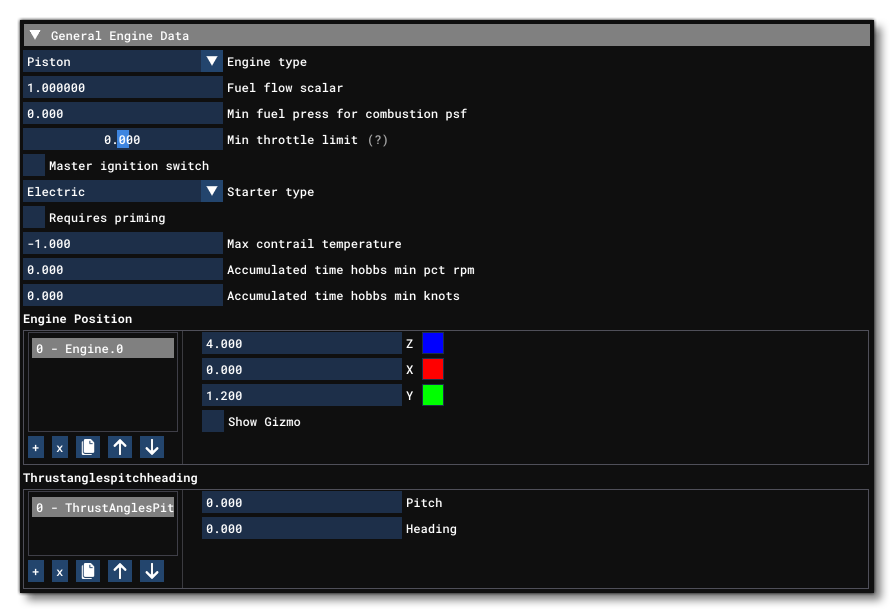

General Engine Data

This section is for setting up the most general of parameters that are related to most, if not all, of the engine types available.

This section is for setting up the most general of parameters that are related to most, if not all, of the engine types available.

- Engine Type: This parameter identifies what type of engine is on the aircraft, and selecting this will affect what other sections and parameters are available, adding or removing them as required for the given engine. Possible engine types are -

- Piston

- Jet

- None

- Helo-turbine (Helicopters)

- Rocket (DO NOT USE - currently not supported)

- Turboprop.

- Fuel Flow Scalar: This is a scalar value for modifying the fuel flow required by the engine(s) with an impact on the rate at which fuel tanks empty only. It allows you to easily adjust the fuel consumption of the engine without changing any other aspect. A value of less than 1.0 causes a slower fuel consumption for a given power setting, a value greater than 1.0 causes the aircraft to burn more fuel for a given power setting.

- Min Fuel Press For Combustion PSF: The minimum fuel pressure required to get combustion (in psf).

- Min Throttle Limit: This value defines the minimum throttle position (as a percentage of the maximum). The value is expressed between -1.0 and 1.0, where a negative value is for engines with a reverse mode. Normally this is 0 for piston aircraft and -0.25 for turbine engine aircraft with reverse thrust.

- Master Ignition Switch: Defines whether the master ignition switch is available or not. If available, this switch must be on for the ignition circuit, and thus the engines, to be operable. Turning it off will stop all engines.

- Starter Type: The engine starter type. Can be one of the following values -

- Electric

- Manual

- Bleed Air

- Requires Priming: If checked, the engine may need to be primed before combustion (depending on temperature).

- Max Contrail Temperature: The ambient temperature below which engine vapor contrails will be turned on. For piston engines, the contrail effect is turned off unless a temperature value is set here, and for turbine engines the effect will occur automatically. Default is -39.724 (for turbine engines above 27,362 ft), or set to -1 for no contrails.

- Accumulated Time Hobbs Min Pct RPM: This can be used to configure the percentage RPM threshold of detection for measuring how long the engine has been running.

- Accumulated Time Hobbs Min Knots: This can be used to configure the airspeed threshold - in Knots - of detection for measuring how long the engine has been running.

After setting the initial parameters you can then add the basic positional information for each of the aircraft engines. These are added by clicking the + button under the Engine sub-section, up to a maximum of 4 engines. You can also select any defined engine and click on the x button to remove it. Each engine added here can then have it's thrust position placed relative to the Datum Reference Point using the Engine Z (Lateral), Engine X (Vertical) and Engine Y (Longitudinal) distance values. You can also enable the Show Gizmo option to place it visually in the simulation. Note that each engine added here will increase the engine count which is internally tracked and used in other parameter calculations. Also note that these coordinates are very important as they will impact the rotation moments generated by engine thrust and will also impact the location of the engine wash.

- Thrust Angles Pitch Heading: This section is for setting the thrust pitch and heading angles (in degrees) for each engine that has been added. You should have the same number of thrust/pitch settings as you do engines, and you add them by clicking the

+button and you can remove them using thexbutton. These angles for each engine are expressed as follows -- the Pitch (theta x) where: <0° is pitch down and >0° is pitch up

- the Heading (theta y) where: <0° is heading left> and 0° is heading right.

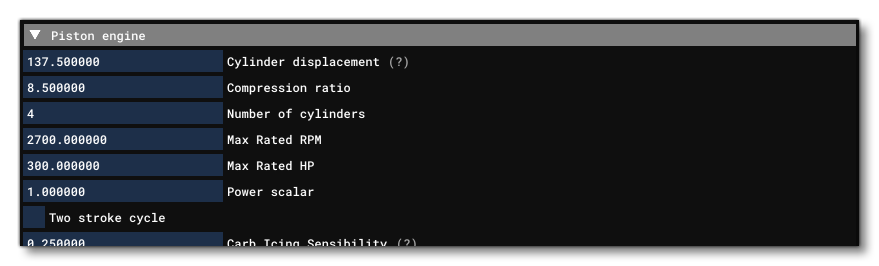

Piston Engine

NOTE: This section will only be visible when the Engine Type is set to Piston.A piston engine's power can be determined through a series of equations that represent the Otto cycle of a four-stroke piston engine, multiplied by the number of pistons available, so this section contains all the information needed to be able to determine how much power the engines are capable of producing. Note that the engine power can also be scaled from the calculated values generated for piston engines with the Power Scalar property.

The parameters available are:

- Cylinder Displacement: The cylinder displacement for each cylinder in cubic inches. This will affect the cylinder torque.

- Compression Ratio: The compression ratio of each cylinder. This will affect the cylinder torque.

- Number Of Cylinders: The engine cylinder count. Will affect the total torque sum of all cylinder torques and the total engine friction of all cylinders.

- Max Rated RPM: The maximum rated RPM of the piston engine. Should be set to the actual aircraft max rated rpm and should not be used to tweak engine performance.

- Max Rated HP: The maximum rated power of the piston engine. Should be set to the actual aircraft max rated power and not be used to tweak engine performance. This value is affected by the Power Scalar. Has a direct impact on fuel flow but no direct impact on engine torque or output power. The output power needs to be adjusted to actually meet this value, as it won't be met automatically.

- Power Scalar: This scalar used to ponderate the Max Rated HP value, scaling the net torque / power output of the engine that is transferred to the propeller. Here is a simplified formula to understand the engine torque output:

textrm{Torque} = power_scalar * ((CylinderTorque * MechanicalEfficiency) - (CylinderFriction * OilViscosity))This formula allows you to understand how the Power Scalar affects the net output.

-

Two Stroke Cycle: Sets whether the engine is a two stroke cycle engine (checked) or not (unchecked).

-

Carb Icing Sensibility: How sensitive the carburetor is to icing.

-

Starter Time: Time (in seconds) during which the starter will be enabled when toggled on.

-

Max Design MP: This parameter works in two "modes" depending on whether the Turbocharged parameter is enabled or not. When enabled, this value indicates the maximum design manifold pressure supplied by the turbocharger, in inHg. When Turbocharged is disabled, this sets the value the manifold pressure regulator should not exceed (essentially the maximum value the regulator will authorize), in inHg.

-

Min Design MP: If the Turbocharged parameter is enabled, this value indicates the minimum design manifold pressure supplied by it, in inHg.

-

Normalised Starter Torque: This value can be modified to increase/decrease the torque supplied by the starter to get the prop turning. Increase this value for a greater torque effect, decrease it for a lower torque setting, and the value cannot go below 0, and is usually less than 1.

-

Auto Ignition: Sets whether auto-ignition is available (checked) or not (unchecked). When auto ignition is absent, magnetos need to be enabled for the engine to function. With auto ignition, there is no need to enable magnetos.

- Shaft Torque TC: Gives the speed at which the shaft torque reaches its target value.

- Carb Heat Delta Temp: Gives the delta of temperature - in Rankine - when the carburetor heater is activated.

- Induction Air Temp TC: Give the speed at which the Induction Air Temp increases to reach its target value.

- Cooling Type: Here you can indicate the method of engine cooling, which can be one of:

- Air Cooled

- Liquid Cooled

- Emergency Boost Type: This parameter is used to indicate the emergency boost type available to the aircraft. The emergency boost system was originally designed to model the systems used on WWII aircraft, however it also models water/methanol systems available for more modern aircraft, and is a way to generate a power setting that is actually above the max continuous rating of the engine. Available options here are:

- None

- Water Injection

- Methanol/Water Injection

- War Emergency Power (WEP)

- Max Emergency Boost Time: The emergency boost duration (in seconds). When this time has elapsed, the engine will be considered as "damaged" and have greatly reduced power. Please see the Notes On Emergency Boost for more information. Default values are 315 seconds for WEP and 312 seconds for methanol-water injection.

- Emergency Boost MP Offset: Additional manifold pressure supplied by emergency boost, if available. Value is in inHg.

- Emergency Boost MP Damage: Defines the manifold pressure above which - when emergency boost is activated and running - the simulation will start measuring how much time you spent with emergency boost running until you reach the time limit. Value is in inHg. Please see the Notes On Emergency Boost for more information.

- Emergency Boost Gain Offset: Multiplier on manifold pressure due to emergency boost. Value must be greater than 0.0 to have any effect.

- Emergency Boost Can Be Stopped: When this is checked, the Emergency Boost can be shut down after it has been engaged. When unchecked, it can't.

- Emergency Boost Throttle Threshold: Threshold at which the emergency boost will boost the engine. This is semi-automatic and will first require that the user activates war emergency power using the simulation input controls (key/gamepad/controller), and then the emergency boost will activate when the throttle goes above the threshold set here. Note that this value is only relevant when the Emergency Boost Type parameter is set to War Emergency Power (WEP).

- Boost Damage Efficiency Factor: This is a factor (expressed as a Percent Over 100) on how much efficiency is affected when WEP is over-used. Value should be greater than 0.

- Turbocharged: Check this to tell the simulation that the engine is turbocharged or uncheck to tell the simulation that it's not. Note that you cannot enable this if the Manifold Pressure Regulator parameter is enabled, as they are mutually exclusive systems.

- Density To Boost Table: This table gives the relation between the ambient air density (in slug / ft³) and the volumetric multiplier of maximum displacement at sea level. In other words, this table scales the potential manifold pressure pre-wastegate. For example, if you wanted to double the maximum available manifold pressure at a pressure altitude of 10,000ft (ISA density of 17.56 slug / ft³), you would use the following values:

17.56 : 2.0

Note that this table is only visible if the Turbocharged parameter is checked, and if you use this table then the Critical Altitude value will be ignored, otherwise it will be used.

- Manifold Pressure Regulator: Controls whether or not the engine has a manifold pressure regulator (checked) or not (unchecked). This regulator limits the air entering the manifold by opening or closing depending on the pressure need. To replicate this the waste gate is used as a limiting factor on the total boost instead of as a boosting factor like in the turbocharger. That means that the

RECIP_ENG_WASTEGATE_POSITIONSimVar will fluctuate between 0% and 100%, and can be monitored. The closer it is to 100% the more it limits the boost. Note that you cannot have a manifold pressure regulator if the Turbocharged parameter is checked, as they are mutually exclusive systems.

- Critical Altitude: The altitude, in ft, at which the turbocharger - if present - will provide the maximum design manifold pressure. Above this altitude, the reciprocating engine will no longer produce its rated horsepower even with its throttle wide open.

- Supercharged: This sets whether the engine is supercharged (checked) or not (unchecked - recommended as this is considered a legacy FSX parameter). If the parameter New Supercharged is set to either Fixed Formula or Multi-Speed Support, then this parameter should be unchecked. Please see the Notes On Supercharger section for additional information on this feature.

- New Supercharged: This sets the engine to use the modern supercharger formulas using one of the 2 possible models. If set to Fixed Formula or Multi-Speed Support, the Supercharged parameter should be unchecked. If set to Off (legacy Aircraft), then the Supercharged parameter may be used (although this is only recommended for legacy FSX aircraft). Please see the Notes On Supercharger section for additional information on this feature.

- Supercharger Altitude Gear: With this parameter you can give the pressure altitude (in ft) at which a specific supercharger gear will be engaged. You can add a maximum of 5 gears, numbered from 1, by clicking the

+button, and you can remove a gear by selecting it and clicking thexbutton. This parameter is only available when New Supercharged is set to Multi-Speed Support, and also requires that Supercharged is unchecked.

- Supercharger Boost High End Gear: With this parameter you can set the high end boost given by the supercharger when in a specific gear. You can add a maximum of 5 gears, numbered from 1, by clicking the

+button, and you can remove a gear by selecting it and clicking thexbutton. This parameter is only available when New Supercharged is set to Multi-Speed Support, and also requires that Supercharged is unchecked.

- Supercharger Boost Low End Gear: With this parameter you can set the low end boost given by the supercharger when in a specific gear. You can add a maximum of 5 gears, numbered from 1, by clicking the

+button, and you can remove a gear by selecting it and clicking thexbutton. This parameter is only available when New Supercharged is set to Multi-Speed Support, and also requires that Supercharged is unchecked.

- Supercharger Boost Low End: This is a multiplier on manifold pressure at low RPM. This parameter is only available when New Supercharged is set to Fixed Formula and Supercharged is unchecked.

- Supercharger Boost High End: This is a multiplier on manifold pressure at high RPM. The actual effect will depend on whether new_supercharged is enabled or not. This parameter is only available when New Supercharged is set to Fixed Formula and Supercharged is unchecked.

- Supercharger Power Cost: Sets the percent of horsepower required to drive the supercharger.

- Manifold Pressure Regulator Threshold: The manifold pressure (in inHg) at which the manifold pressure regulator will start having an effect.

- Manifold Pressure Regulator TC: The manifold pressure time constant.

- Manifold Efficiency Table: This table gives the relationship between the throttle input and it's effect on manifold - essentially giving a way to change the engine idle RPM. You can add a maximum of 47 elements by clicking the

+button, and you can remove an element by selecting it and clicking thexbutton. Each element is a point defined by a throttle position and an manifold efficiency scalar.

- Manifold Pressure Correction By RPM: With this value you can correct the manifold pressure when the relative RPM does not match the throttle position, multiplying the difference using this coefficient. The value is given in inHg and is not limited.

- Manifold Pressure Min: This value limits the minimum final value of the manifold pressure. The value is given is given in inHg and cannot be negative. Note that the final manifold pressure minimum will depend on atmospheric pressure as well, being whichever of the two is lower: this parameter, or the atmospheric pressure.

- Detonation Onset: The manifold pressure (in psi) that - if reached or exceeded - will lead to the engine detonating.

- Min Cruise RPM: The minimum RPM for cruise speed.

- Max Cruise RPM: The maximum RPM for cruise speed.

- Max Indicated RPM: The maximum RPM to be shown in the UI RPM indicator instrument.

NOTE: This has no influence on the flight model of the aircraft.

- Min Required RPM: The minimum required RPM to prevent the engine from shutting down.

- Max RPM Mechanical Efficiency Scalar: This is a scalar value that can be modified to tune the mechanical efficiency of the engine at maximum RPM in combination with the Engine Mechanical Efficiency Table. Increase this value to increase the mechanical efficiency, decrease it to decrease the mechanical efficiency. This is one of the mechanical efficiency scalars that will be applied to the torque formula:

Torque = power_scalar * ((CylinderTorque * engine_mechanical_efficiency_table) - (CylinderFriction * OilViscosity))

- Idle RPM Mechanical Efficiency Scalar: This is a scalar value that can be modified to tune the mechanical efficiency of the engine at idle RPM in combination with the Engine Mechanical Efficiency Table. Increase this value to increase the mechanical efficiency, decrease it to decrease the mechanical efficiency. This is a modifier that will be used along with the engine_mechanical_efficiency_table.This is one of the mechanical efficiency scalars that will be applied to the torque formula:

Torque = power_scalar * ((CylinderTorque * engine_mechanical_efficiency_table) - (CylinderFriction * OilViscosity))

- Low RPM Shake Scalar: This scalar value is used to add a realistic shaking motion to piston aircraft based on the number and RPM of the engines.

- Max RPM Friction Scalar: This is a scalar value that can be modified to tune the internal friction of the engine at maximum RPM in combination with the Engine Mechanical Efficiency Table. Increase this value to increase the friction, decrease it to decrease the friction. This is one of the mechanical efficiency scalars that will be applied to the torque formula:

Torque = power_scalar * ((CylinderTorque * engine_mechanical_efficiency_table) - (CylinderFriction * OilViscosity))

- Idle RPM Friction Scalar: This is a scalar value that can be modified to tune the internal friction of the engine at idle RPM in combination with the Engine Mechanical Efficiency Table. Increase this value to increase the friction, decrease it to decrease the friction. This is one of the mechanical efficiency scalars that will be applied to the torque formula:

Torque = power_scalar * ((CylinderTorque * engine_mechanical_efficiency_table) - (CylinderFriction * OilViscosity))

- RPM To Oil Pressure Table: This table gives the relation between the percentage Max RPM and the percentage maximum Oil Pressure in a table with up to 47 elements. You can add elements by clicking the

+button, and you can remove elements by selecting them and clicking thexbutton.

- RPM To Fuel Pressure Table: This table gives the relationship between the percentage RPM and the percentage Fuel Pressure in a table with up to a 47 elements. You can add elements by clicking the

+button, and you can remove elements by selecting them and clicking thexbutton. The formula for calculating the fuel pressure is as follows:FuelPress = fuel_press_tuning_constant * fuel_press_max * rpm_to_fuel_pressure_table

- RPM On Cht Table: This table gives the relationship between the RPM - as a percentage of maximum - and the CHT (cylinder head temperature) - as a percentage of maximum - in a table of up to 47 elements. You can add elements by clicking the

+button, and you can remove elements by selecting them and clicking thexbutton.

- Engine Mechanical Efficiency Table: This table represents the engine rotation speed (RPM) versus the different mechanical Efficiency Factors for the given speeds. This is the mechanical efficiency table that will be applied to the torque formula, modified by the values in the tables Max RPM Mechanical Efficiency Scalar and Idle RPM Mechanical Efficiency Scalar. Essentially you can set this table as required and then tune it by using the other two table parameters. These tables are multipliers that will affect every entry in this table but with a different magnitude:

- The Max RPM Mechanical Efficiency Scalar will have a greater effect on the last entries of the table (high rpm points)

- The Idle RPM Mechanical Efficiency Scalar will have greater effect on the first entries of the table (low rpm points)

Torque = power_scalar * ((CylinderTorque * engine_mechanical_efficiency_table) - (CylinderFriction * OilViscosity))

- Engine Friction Table: Defines the friction/torque applied to the engine - especially when shutting down - using a 2D table of 7 paired values. You can add elements by clicking the

+button, and you can remove elements by selecting them and clicking thexbutton, and each element requires you to set the RPM for engine rotation speeds correlated with the torque in ftlbs. This is one of the friction scalars that will be applied to the cylinder friction as part of the torque formula. Here is a simplified version of the torque formula to understand how mechanical efficiency works:Torque = power_scalar * ((CylinderTorque * engine_mechanical_efficiency_table) - (CylinderFriction * OilViscosity))

- EGT Tuning Constant: The EGT tuning coefficient, which is a global scalar of the exhaust gas temperature. This is the EGT calculation formula:

EGT = egt_tuning_constant * (egt_peak_temperature * egt_factor_from_pct_power + egt_delta_from_mixture_ratio)

- EGT Peak Temperature: The EGT peak temperature, in Rankine (calculated as °F + 460). This is the EGT calculation formula:

EGT = egt_tuning_constant * (egt_peak_temperature * egt_factor_from_pct_power + egt_delta_from_mixture_ratio)

- EGT TC: The EGT time constant, in seconds. This defines at which speed the effective EGT will reach the target EGT based on the current situation. The time constant formula works like this:

CurrentEGT} = (EGT - CurrentEGT) * DeltaTime * EGTtc

- PCT Power To EGT Factor: With this table you can create a correlation between the percentage of power (hp/maxhp) and the EGT factor (to EGT Peak Temperature). You can add elements by clicking the

+button, and you can remove elements by clicking the-button.

- Mixture Ratio to EGT Delta: With this table you can create a correlation between the mixture ratio and the EGT temperature delta (to current EGT value after factor is applied). You can add elements by clicking the

+button, and you can remove elements by clicking the-button.

- CHT Tuning Constant: Cylinder head temperature tuning constant, which is the global scalar of the cylinder head temperature. This is the CHT calculation formula:

CHT = CHTTuningConst * ((CHTHeatingConst * RPMCHTTable) - (CHTCoolingConst * CHTCooling)) NOTE: The CHTCooling value is explained here: CowlFlapPct

- CHT Cooling Constant: Cylinder head temperature cooling constant, which is the scalar of the cylinder head temperature cooling. This is the CHT calculation formula:

CHT = CHTTuningConst * ((CHTHeatingConst * RPMCHTTable) - (CHTCoolingConst * CHTCooling)) NOTE: The CHTCooling value is explained here: CowlFlapPct

- CHT Heating Constant: Maximum cylinder head temperature in Rankine. This is the CHT calculation formula:

CHT = CHTTuningConst * ((CHTHeatingConst * RPMCHTTable) - (CHTCoolingConst * CHTCooling)) NOTE: The CHTCooling value is explained here: CowlFlapPct

- CHT TC: Cylinder head temperature time constant, in seconds.

- CHT Liquid Max Cooling: Maximum temperature - in Rankine - that the liquid cooling system of the cylinder head temperature can dissipate.

- Oil Press Tuning Constant: Oil pressure tuning constant, which is an intermediate scalar of oil pressure. This is the oil pressure formula:

OilPressure = OilPressTuningConstant * (OilPressMax * OilTempFactorFromRPM + OilTempToOilPressureTable) + PropLeverPosToOilPressureDeltaTable - AnyOilLeakage

- Oil Press Max: The maximum permitted oil pressure in psf. This is the oil pressure formula:

OilPressure = OilPressTuningConstant * (OilPressMax * OilTempFactorFromRPM + OilTempToOilPressureTable) + PropLeverPosToOilPressureDeltaTable - AnyOilLeakage

- Oil Press TC: Oil pressure time constant used to define at which speed the effective oil pressure will reach the target oil pressure based on the current situation. The time constant formula works like this:

CurrentOilPress = (OilPress - CurrentOilPress) * DeltaTime * OilPressTCDefault

- Oil Temp Tuning Constant: Oil temperature tuning constant, a global scalar of the oil temperature. This is the oil temperature calculation formula:

OilTemp = OilTempTuningConstant * (OilTempHeatingConstant * OilTempFactorRPM) - (OilTempCoolingConstant * OilCooling)

- Oil Temp Cooling Constant: Oil temperature cooling constant, a scalar of the oil temperature cooling system. This is the oil temperature calculation formula:

OilTemp = OilTempTuningConstant * (OilTempHeatingConstant * OilTempFactorRPM) - (OilTempCoolingConstant * OilCooling)

- Oil Temp Heating Constant: Oil temperature heating constant defining the maximum oil temperature, in Rankine. This is the oil temperature calculation formula:

OilTemp = OilTempTuningConstant * (OilTempHeatingConstant * OilTempFactorRPM) - (OilTempCoolingConstant * OilCooling)

- Oil Temp TC: Oil temperature time constant, in seconds. This is used to define at which speed the effective oil temperature will reach the target oil temperature based on the current situation. The time constant formula works like this:

CurrentOilTemp = (OilTemp - CurrentOilTemp) * DeltaTime * OilTempConstDefault

- Oil Temp To Pressure: This table gives the pressure differential (in psf) of the oil depending on the temperature (in Rankine) of the oil in a table of up to 47 elements. You can add elements by clicking the

+button, and you can remove elements by clicking the-button. This is the oil pressure formula:OilPressure = OilPressTuningConstant * (OilPressMax * OilTempFactorFromRPM + OilTempToOilPressureTable) + PropLeverPosToOilPressureDeltaTable - AnyOilLeakage

- RPM To Oil Temp Factor: This table gives the oil temperature factor (to Oil Temp Tuning Constant) from RPM in a table of up to 5 elements. You can add elements by clicking the

+button, and you can remove elements by clicking the-button.

- Prop Lever Pos To Oil Pressure Delta: This table defines the delta in psf of the oil pressure depending on the propeller lever position (from 0 - 1) in a table of up to 47 elements. You can add elements by clicking the

+button, and you can remove elements by clicking the-button.NOTE: This parameter can also be applicable to Turboprop Engines, but only when the aircraft has featherable propellers.

- Oil Coolant Flaps Effect: Sets the maximum temperature - in Rankine - that the oil coolant flaps can dissipate.

- Radiator Cooling Constant: Radiator cooling constant which is used to scale the radiator cooling. This is the radiator temperature calculation formula:

RadTemp = RadTuningConst * (RadHeatConst * RadTempTable - RadCoolConst * RadCool)

- Radiator Heating Constant: Radiator heating constant, defining the maximum radiator temperature. This is the radiator temperature calculation formula:

RadTemp = RadTuningConst * (RadHeatConst * RadTempTable - RadCoolConst * RadCool)

- Radiator TC: Radiator time constant which defines the speed at which the effective radiator temperature will reach the target radiator temperature based on the current situation. The time constant formula works like this:

CurrentRadTemp = (RadTemp - CurrentRadTemp) * DeltaTime * RadTempConst

- Radiator Tuning Constant: Radiator tuning constant, used as a global scalar of the radiator temperature. This is the radiator temperature calculation formula:

RadTemp = RadTuningConst * (RadHeatConst * RadTempTable - RadCoolConst * RadCool)

- Radiator Coolant Flaps Effect: the maximum temperature - in Rankine - that the radiator coolant flaps can dissipate.

- Diesel: If checked then the engine is a diesel engine, in which case it will have no mixture and no magneto. If unchecked then the engine is not a diesel engine.

- Fuel Metering: This is used to indicate the fuel metering type, which is the ECU or the ICU deciding how much fuel to inject into the cylinder. The available options are:

- Fuel Injected

- Gravity Carburetor

- Aerobatic Carburetor

- Fuel Air Auto Mixture: When checked, this tells the simulation that automixture is available. If checked, the mixture will automatically be set for maximum performance. When set to manual (unchecked), the mixture needs to be manually adjusted to maintain the required performance.

- Best Power SFC: This value sets the specific fuel consumption at the best power mixture ratio per currently produced unit of net output power. This value is used in the fuel flow / fuel consumption formula.

- Use Volumetric Fuel Flow: Sets whether the engine simulation uses a volumetric based fuel flow computation (TRUE, 1) instead of the computation based on Best Power SFC (FALSE, 0). In this mode, the fuel flow will be based on the current mass air flow through the engine multiplied by the mixture ratio, with the volume of air per engine cycle defined by:

number_of_cylinders * cylinder_displacement * volumetric_efficiency

The volumetric efficiency for this fuel calculation can be adjusted per RPM using the optional RPM On Volumetric Efficiency parameter, which, if not present, defaults to 0.85 (85% volumetric efficiency) for all RPM values. Fuel will continue to flow based on metered volume even if no power is being delivered (too rich or too lean), except in the case of fuel injected engines with no power to at least one magneto.

-

RPM On Volumetric Efficiency: Gives the relationship between RPM and pre-boost volumetric efficiency from 0 (0% volumetric efficiency) to 1 (100% volumetric efficiency). The table is used to scale the volume of air ingested by the engine per engine cycle as part of the fuel consumption computations, which allows the fuel consumption of the engine to be adjusted across the RPM range. This table only affects the fuel consumption computation if the Use Volumetric Fuel Flow parameter is checked.

- Use Intake Density On Mixture: Sets whether the engine simulation uses the post-boost air density to compute the mixture ratio (enabled), instead of the ambient air density (disabled). This allows the fuel/air mixture ratio to follow the boost density so that leaning is not required until the compressor can no longer supply sea level or above density air to the engine. This parameter only has an effect on engines where Emergency Boost Type is set or Supercharged, New Supercharged, or Turbocharged is enabled.

- Mixture Lever To Ratio Table: Gives the relation between the mixture lever position (from 0 to 1) to the fuel/air mixture ratio at sea level, defined as a decimal of the ratio of fuel over air. In a piston engine, the stoichiometric fuel/air ratio is generally given as 1/14.7 or 0.068027.

- Mixture Ratio To SFC Scalar: Describes what the desired fuel consumption scalar is at a given fuel mixture ratio.

-

Mixture Ratio To Engine Efficiency Table: Gives the relation between the fuel/air mixture ratio and the engine power efficiency scalar, with 1.0 giving the maximum defined power output. Values beyond 1.0 can be given to exceed the maximum defined engine power. This table can be used to adjust the ideal power to mixture ratio curve for a given engine design.

- Fuel Press Tuning Constant: This defines the fuel pressure tuning constant, which is the global scalar of the fuel pressure. This is the fuel pressure calculation formula:

FuelPress = FuelPressTuningConstant * FuelPressMax * RpmToFuelPressureTable

NOTE: This is for legacy fuel only and will only be visible when Use Legacy Fuel is checked.

- Fuel Press Max: Maximum permitted fuel pressure, in psf. This is the fuel pressure calculation formula:

FuelPress = FuelPressTuningConstant * FuelPressMax * RpmToFuelPressureTable

NOTE: This is for legacy fuel only and will only be visible when Use Legacy Fuel is checked.

- Fuel Press Time Constant: Fuel pressure time constant, in seconds.

NOTE: This is for legacy fuel only and will only be visible when Use Legacy Fuel is checke

- Number Of Magnetos: Sets the number of magnetos in the engine.

- Magneto Order Left Right Both: Sets the order of the magneto switch direction, which can be one of the following:

- OFF - LEFT - RIGHT - BOTH - START

- OFF - RIGHT - LEFT - BOTH - START

- Single Magneto Efficiency: Gives the efficiency ratio of the engine if it is designed for 2 magnetos but only 1 is currently active.

- Plasma Ignition: This defines whether the aircraft has a plasma ignition system (checked) or not (unchecked).

- Single Plasma Efficiency: This value is used to indicate the percentage of power delivered when only the plasma is on compared to when both the plasma and magneto are on. The value is expressed as a Percent Over 100, where 1 would mean that the plasma has the same power as both the magneto and plasma working together.

- Recip Stop Arc Degrees: Gives the amplitude of the motion made by a reciprocating engine while it is having a spring compression behavior after it stops producing work.

NOTE: This will only be visible if Use Legacy is checked.

- Recip Stop Arc Restitution: Gives the amount of torque in percentage restituted when reaching its max arc by a reciprocating engine while it is having a spring compression behavior after it stops producing work.

NOTE: This will only be visible if Use Legacy is checked.

- Recip Stop Arc Max Pct RPM: Gives the percentage max RPM at which a reciprocating engine that stopped producing work will start having a spring compression behavior.

NOTE: This will only be visible if Use Legacy is checked.

- Recip Stop Arc Friction Factor: Factor on how much friction affects the reciprocating engine while having a spring compression behaviour.

NOTE: This will only be visible if Use Legacy is checked.

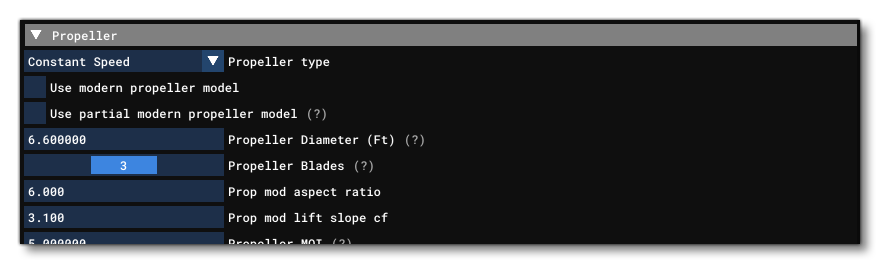

Propeller

This section is for defining the properties of the propellers on a piston or turboprop aircraft. The parameters available are:

- Propeller Type: This sets the propeller type being used by the aircraft. Available options are:

- Constant Speed

- Fixed Pitch

-

Use Modern Propeller Model: When this is checked, the simulation will use the modern version of the propeller model, instead of the legacy version. Enabling this will provide additional parameters to more precisely determine the behaviour and effects of the propellers on an aircraft.

- Use Partial Modern Propeller Model: When un-checked, the simulation will partially switch to the modern prop simulation but not feed back the modern absorbed torque value into the engine system. When checked the full modern prop simulation for the absorbed torque will be used.

- Propeller Diameter: This sets the diameter of propeller blades from tip to tip, in ft. Will define the propeller disc area and therefore the amount of air mass that will be accelerated by the propeller. Disc area, RPM and pitch will impact the absorbed power and therefore propeller thrust.

- Propeller Blades: This value indicates the number of blades on the propeller. Value can be 2, 3, or 4 only. Propellers with more blades absorb more power and provide more thrust but should be less efficient.

- Prop Mod Aspect Ratio: This parameter can be used to define the aspect ratio of a single propeller blade (a value usually between 4 and 6). A smaller aspect ratio increases the area of the propeller and therefore the output thrust/power, but it also increases the absorbed torque and therefore requires more engine power.

NOTE: This parameter will only be visible when Use Modern Propeller Model is checked.

- Prop Mod Lift Slope CF: This defines the lift slope gradient of the propeller surface lift polar, a value usually between 3 and 6 (the theoretical maximum for a "perfect" propeller is \(2\pi\) ). This value will directly impact the propeller power output.

NOTE: This parameter will only be visible when Use Modern Propeller Model is checked.

- Propeller MOI: MOI of the propeller, axis and all connected moving parts, in Slug sqft. This moment of inertia will define at what speed the engine will reach it's stable RPM. A large MOI results in an engine taking a lot of time going up into RPM, and the smaller this value is, the faster the propeller will adjust its RPM when the throttle is adjusted.

- Use Propeller RPM: Tells the 3rd person view HUD interface which unit to use for the RPM indication, one of the following:

- Engine RPM

- Propeller RPM

- Beta Max: Maximum blade pitch angle in degrees for a constant speed prop.

NOTE: This parameter is only available when Propeller Type is set to Fixed Pitch.

- Beta Cruise: The cruise blade pitch angle in degrees for a constant speed prop.

NOTE: This parameter is only available when Propeller Type is set to Fixed Pitch.

- Beta Min: Minimum blade pitch angle in degrees for constant speed prop.

NOTE: This parameter is only available when Propeller Type is set to Fixed Pitch.

- Prop Mod Beta Def At Ratio: This is the ratio at which the prop beta is defined, as a Percent Over 100. Usually this value is in the POH plus 75%, which means that when you set propeller pitch to 20° at 75%, then the propeller angle is 20° at 75% outside.

- Min Governed RPM: The minimum RPM controlled by the governor for a constant speed prop. For variable pitch propellers, this will be the RPM the system will try to reach when the RPM lever is set to the minimum value.

- Prop TC: Time constant, in seconds, for the propeller pitch angle changes. The formula used is:

CurrentPitch = (TargetPitch - CurrentPitch) * PropTC * DeltaTime

- Prop Governor P: The propeller governor controller P value. Part of the full PID definition for the propeller.

- Prop Governor I: The propeller governor controller I value. Part of the full PID definition for the propeller.

- Prop Governor D: The propeller governor controller D value. Part of the full PID definition for the propeller.

- Prop Governor I Boundary: The propeller governor controller I boundary.

- Prop Governor D Boundary: The propeller governor controller D boundary.

- Prop CX Min: Value of the propeller \(C_x\) when beta = 0.

- Prop CX At Cruise Beta: Value of the propeller \(C_x\) when beta = beta_max

- Prop CX Parabol: Whether to use the legacy or modern calculation for \(C_x\). If unchecked, then the legacy interpolation equations will be used, if checked then the modern parabolic equations will be used.

- Gear Reduction Ratio: The reduction ratio from the engine output RPM to prop RPM.

- Low Speed Theory Limit: The speed at which low-speed propeller theory gets blended into the high speed propeller theory, measured in ft per second. With the legacy FSX propeller model, the simulation did not work at low airspeeds and a fall back simpler simulation was used at lower speeds. So, this parameter allows you to define the speed below which to change simulation. With the modern flight model, the propeller simulation works at all speeds, including reverse, and there is no need to fallback to the low speed theory.

NOTE: This will only be visible if Use Legacy is checked.

- Min Eng RPM Engage Prop: Value of engine RPM below which the propeller is no longer engaged with the engine and becomes free.

- Max Prop RPM Pct Extend Prop: Allows you to define the Percent of Max RPM at which the propeller is fully extended. The value is expressed as a Percent Over 100, but it can also be set to -1 which will force the propeller to always be fully extended.

- Prop Engage TC: Speed at which the propeller engages when going above the RPM threshold.

- Prop Disengage TC: Speed at which the propeller disengages when going below the RPM threshold.

- Fixed Pitch Beta: Propeller pitch, in degrees, that will be used for fixed pitch propellers and all other pitch values will be ignored.

- Prop Sync Available: When checked, this indicates that propeller-sync is available for twin engine aircraft. If synchronization between propellers is available then both engines spin at the same RPM.

- Prop Deice Available: This indicates if propeller de-icing is available (checked) or not (unchecked).

- Thrust Scalar: The propeller thrust scalar, which is a global scalar of propeller thrust applied at the end of the thrust calculation. Here is the thrust formula:

Thrust} = ThrustScalar * ThrustEfficiency * PowerAbsorbed / Airspeed

- Prop Use Legacy Tables: By default, propeller efficiency and power coefficients are calculated automatically by Microsoft Flight Simulator using the following parameters: Prop Scale Power Abs, Prop Eff Min Val, Prop Eff Max Smooth, Prop Falloff Power, Prop Falloff Coef, Prop Low Beta Reduction Mid, Prop Low Beta Reduction. However you may prefer to tweak these values manually using "legacy" tables (although this is not recommended). If that is the case, then this parameter should be checked. When checked, it means that the parameters listed above will no longer be available, and the following tables will need to be filled in correctly: Prop Efficiency Table, Prop Power CF.

- Prop Scale Power Abs: A scalar value used when calculating the absorbed power by the propeller. Formula uses this value and the number of propeller blades divided by 2.

NOTE: Only available and used when Prop Use Legacy Tables is checked.

- Prop Eff Min Val: The minimum thrust efficiency of the propeller.

NOTE: Only available and used when Prop Use Legacy Tables is checked.

- Prop Eff Max Smooth: This parameter allows you to add more thrust efficiency at the upper range of the thrust efficiency curve.

NOTE: Only available and used when Prop Use Legacy Tables is checked.

- Prop Falloff Coef: This is the propeller power curve falloff coefficient.

NOTE: Only available and used when Prop Use Legacy Tables is checked.

- Prop Falloff Power: This parameter allows you to define the drop in power of the curve of thrust efficiency at the upper range of the curve.

NOTE: Only available and used when Prop Use Legacy Tables is checked.

- Prop Low Beta Reduction: This parameter allows you to define the thrust efficiency reduction when the beta is far from Prop Low Beta Reduction Mid.

NOTE: Only available and used when Prop Use Legacy Tables is checked.

- Prop Low Beta Reduction Mid: This parameter allows you to define the beta at which the thrust efficiency will be maximum.

NOTE: Only available and used when Prop Use Legacy Tables is checked.

- Prop Reverse Available: Specifies the scalar on the calculated propeller reverser effect. A value of 0 will cause no reverse thrust to be available. A value of 1.0 will cause the theoretical normal thrust to be available. Other values will scale the normal calculated value accordingly.

- Min On Ground Beta: Minimum blade pitch angle when the aircraft is on the ground, in degrees.

- Min Reverse Beta: Minimum blade pitch angle when the propeller is in reverse, in degrees.

- Max Reverse Vel: This is the maximum backwards aircraft velocity, in ft per second, when the propeller is reversed. As you approach this maximum speed in reverse, the prop thrust is reduced to 0. If Prop Reverse Available is greater than 0, then this value must also be greater than 0.

- Prop Feathering Available: This indicates if propeller feathering is available (checked) or not (unchecked). If feathered, the propeller will move to the Beta Feather pitch.

- Prop Auto Feathering Available: This indicates if propeller auto feathering is available (checked) or not (unchecked). If feathered, the propeller will move to the Beta Feather pitch.

- Min N1 For Autofeather Armed: Minimum percentage N1 before the AutoFeather system arms itself.

NOTE: This parameter is only used by Turboprop Engines and only when Prop Auto Feathering Available is checked.

- Max N1 For Autofeather Actuated: The maximum percentage N1 below which the armed AutoFeather system starts to feather the propeller.

NOTE: This parameter is only used by Turboprop Engines and only when Prop Auto Feathering Available is checked.

- Min RPM For Feather: The minimum RPM at which the prop will feather.

- Power Absorbed CF: Coefficient of friction for power absorbed by a feathered propeller. More power absorbed means more torque and thus more power is required to spin the propeller, but this also means more thrust when the propeller spins.

- Power Propeller Absorbed CF: This is a scalar which is applied to the absorbed power of the propeller in normal mode.

NOTE: Setting this value is only required if the Prop Efficiency Table is not used and Prop Use Legacy Tables is unchecked.

- Defeathering Accumulators Available: Value to indicate if de-feathering oil accumulators are available (checked) or not (unchecked).

- Feathering Switches: This is for indicating if feathering switches are available (checked) or not (unchecked). Feathering switches (as found on the Douglas DC3, for example), allowing the pilot to automatically feather the propeller via a switch, regardless of the propeller lever position.

-

Prop Efficiency Table: The propeller thrust efficiency table formatted as an nD table (14 values per row, up to 12 rows) that defines thrust efficiency based on advance ratio and propeller pitch.

NOTE: This table is only available when the Prop Use Legacy Tables parameter is checked, otherwise a formula using other parameters is used instead.

-

Prop Power CF: The propeller power coefficient formatted as an nD table (14 values per row, up to 12 rows) that defines power absorption based on advance ratio and propeller pitch.

NOTE: This table is only available when the Prop Use Legacy Tables parameter is checked, otherwise a formula using other parameters is used instead.

-

Prop Mod AoA Lift Delta Deg: This is the offset angle, in degrees, of the propeller's zero lift AoA. This means that the propeller will provide zero thrust at a pitch of the propeller beta minus the degrees of the AoA lift delta.

NOTE: This parameter is only available when the Use Modern Propeller Model parameter is checked.

-

Prop Mod Stall AoA Scaler: This is the stall scaler, which is a coefficient that controls the angle at which the airflow will detach from the surface (the propeller surface, like any wing surface, will have a stall behavior if the incoming air AoA angle exceeds a specific value of 15° to 25°). To simulate this stall behavior, the simulation will use an approximation function which is applied to the surface \(C_x\) (ie: the lift slope) and the surface drag efficiency.

NOTE: This parameter is only available when the Use Modern Propeller Model parameter is checked.

-

Prop Mod Stall AoA Power: This is the coefficient of the power function that is applied to the stall formula. Choosing a power different to the default (2) completely shifts the curve and requires a different scale value (see prop_mod_stall_aoa_scaler).

NOTE: This parameter is only available when the Use Modern Propeller Model parameter is checked.

-

Prop Mod AoA Twist Delta Deg: With this parameter you can add a delta - in degrees - to the propeller twist. When we say "twist" what we mean is that when a propeller has (for example) 20° pitch, it actually has 20° of pitch only at a specific ratio (usually 0.75). Outside of that ratio, the pitch is smaller, and inside of it the pitch is bigger. So this value can change the way it twists, making it more "flat" or more "twisted". This basically makes a propeller more optimum for take off or cruise.

NOTE: This parameter is only available when the Use Modern Propeller Model parameter is checked.

-

Prop Mod Lift Efficiency CF: This is the propeller surface induced drag coefficient.

NOTE: This parameter is only available when the Use Modern Propeller Model parameter is checked.

-

Prop Mod Zero Lift Drag CF: This is the propeller surface based drag coefficient.

NOTE: This parameter is only available when the Use Modern Propeller Model parameter is checked.

-

Prop Mod Reverse Left: This can be used to reverse the direction of the propeller(s) on the left of the aircraft. Generally only used to align the propeller animation with the simulation.

NOTE: This parameter is only available when the Use Modern Propeller Model parameter is checked.

-

Prop Mod Reverse Right: This can be used to reverse the direction of the propeller(s) on the right of the aircraft. Generally only used to align the propeller animation with the simulation.

NOTE: This parameter is only available when the Use Modern Propeller Model parameter is checked.

-

Prop Mod Reverse Centre: This can be used to reverse the direction of the propeller(s) on the center of the aircraft. Generally only used to align the propeller animation with the simulation.

NOTE: This parameter is only available when the Use Modern Propeller Model parameter is checked.

-

Prop Mod Ang Offset Left: This parameter can be used to offset the angle of rotation of the propeller(s) on the left of the aircraft. Generally only used to fully align the simulation forces with the animation (you can visualise these forces using The Aircraft Editor option to debug Sim Forces).

NOTE: This parameter is only available when the Use Modern Propeller Model parameter is checked.

-

Prop Mod Ang Offset Right: This parameter can be used to offset the angle of rotation of the propeller(s) on the right of the aircraft. Generally only used to fully align the simulation forces with the animation (you can visualise these forces using The Aircraft Editor option to debug Sim Forces).

NOTE: This parameter is only available when the Use Modern Propeller Model parameter is checked.

-

Prop Mod Ang Offset Centre: This parameter can be used to offset the angle of rotation of the propeller(s) on the center of the aircraft. Generally only used to fully align the simulation forces with the animation (you can visualise these forces using The Aircraft Editor option to debug Sim Forces).

NOTE: This parameter is only available when the Use Modern Propeller Model parameter is checked.

-

Prop Mod Moment Scalar Pitch: This parameter permits you to tweak the effect on the pitch moment of the propeller if the default values are too strong or weak. In general this value should not require changing from the default.

NOTE: This parameter is only available when the Use Modern Propeller Model parameter is checked.

-

Prop Mod Moment Scalar Yaw: This parameter permits you to tweak the effect on the yaw moment of the propeller if the default values are too strong or weak. In general this value should not require changing from the default.

NOTE: This parameter is only available when the Use Modern Propeller Model parameter is checked.

-

Prop Mod Moment Scalar Roll: This parameter permits you to tweak the effect on the roll moment of the propeller if the default values are too strong or weak. In general this value should not require changing from the default.

NOTE: This parameter is only available when the Use Modern Propeller Model parameter is checked.

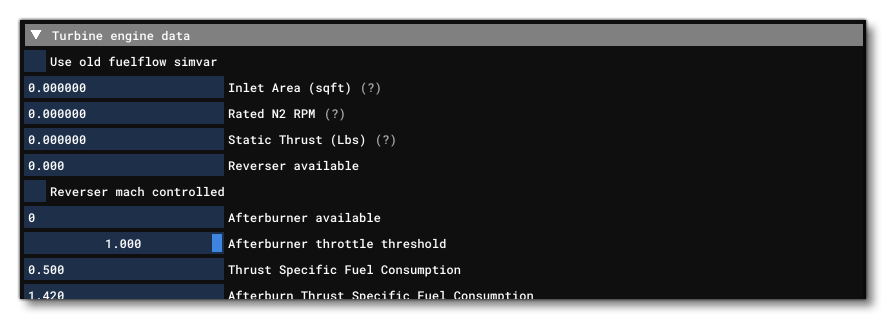

Turbine Engine Data

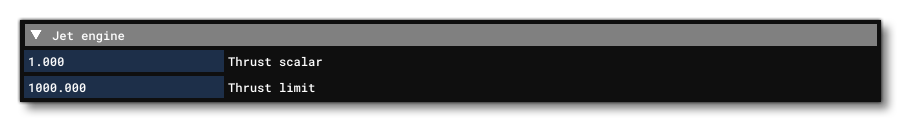

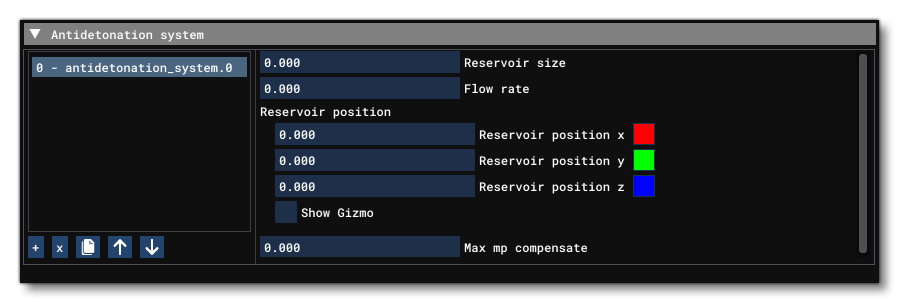

This section is for defining the properties of the turbine engines for an aircraft. Note that most of the parameters here are also used by turboprop aircraft and will require that the Turboprop Engine section be set up correctly (those parameters that aren't used by TurboProps will be signaled in the descriptions as being Jet only). This also means that some parameters will be shown/hidden in the editor depending on the engine type being defined.

The available parameters are:

- Use Old Fuelflow Simvar: When unchecked the fuel system will use the modern fuelflow calculations, based on the internal engine simulation corrected fuel flow computations, which means that this internal corrected fuelflow needs to be correctly parametered in order to get the desired consumption. When checked it will use the old FSX way of doing things, which requires setting the Thrust Specific Fuel Consumption, as well as the AfterBurner Thrust Specific Fuel Consumption parameters (for Jets) or Power Specific Fuel Consumption (for TurboProps).

- Inlet Area: The engine nacelle inlet area, in sqft. This value will scale the ram drag of the turbine in order to use a normalized Corrected Airflow Table.

- Rated N2 RPM: The second stage compressor rated RPM at 100%.NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- Use Gross Thrust On Fuelflow: When checked, this will calculate turbine fuel flow based on the gross thrust of the engine. If unchecked and Use Old Fuelflow Simvar is unchecked as well, fuel flow will be based on the fuel controller target. When unchecked and Use Old Fuelflow Simvar is checked, fuel flow wil be based on net thrust.

- Static Thrust: The maximum rated static thrust at Sea Level, in lbs, at 100% thrust.

NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet". For turboprop engines, thrust is generated by propellers.

- Reverser Available: This scalar value is used to set the power available when in reverse. When set to 0, reverser thrust will not be available, and values greater than 0 will be used as the thrust scalar when in reverse.NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- Reverser Mach Controlled: This value allows you to define if a mach controller reverser nozzle is available. If checked then it is, if unchecked then it isn't. Mach controller reverser nozzles don't use the Reverser Available scale but a mach based table scale instead.NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- Afterburner Available: An integer value indicating the number of afterburner stages available.NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- Afterburner Throttle Threshold: The throttle range when the afterburner engages, expressed as a Percent Over 100.NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- Thrust Specific Fuel Consumption: The rate of fuel burnt to produce a unit of thrust expressed as a percentage. This is specifically the ratio of fuel used in lbs per hour compared to thrust in pounds (applies at all speeds).

NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- AfterBurner Thrust Specific Fuel Consumption: The rate of fuel burnt to produce a unit of thrust when afterburners are active. This is specifically the ratio of fuel used in lbs per hour compared to thrust in pounds (applies only when the afterburner is active and will be used instead of the default Thrust Specific Fuel Consumption parameter).

NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- Afterburner On Thrust Table: This table takes the mach value and a thrust multiplier and outputs a scalar on thrust for maximum afterburner, scaled by the percentage of afterburner active. To add a set of values to the table use the + button, and to remove one, select it and click the x button. This table is only used when Afterburner Available is set to a value greater than 0.

NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- Use N2 To N1 Table: Defines whether or not to use the N2 To N1 Table. When checked this table will be used. When unchecked, the N1 will be calculated based on a formula using High N1, Low Idle N1, High N2, Low Idle N2 and Mach Influence On N1.

NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- N2 To N1 Table: This table is used to convert N2 values into to N1 values based on the Mach value. NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- Use Commanded Ne Table: Defines whether or not use the Mach 0 Corrected Commanded Ne Table and Mach Hi Corrected Commanded Ne Table. When checked these tables will be used. When unchecked, the commanded Ne will be a linear interpolation between idle N1 and 100% N1 based on the throttle input, and the commanded N2 will be equal to the commanded Ne and an N2 to N1 conversion will occur. However, when these tables are used, the commanded N1 will be equal to the commanded Ne.NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- Mach 0 Corrected Commanded Ne Table: The commanded N2 (corrected) vs. throttle table when at 0 Mach. This table of values uses the delta pressure ratio and the throttle position to calculate a minimum Mach which is then used to generate the corrected N2 value. Note that we use the inverse of delta pressure ratio (Psl/P) so that values are in increasing order, and we give values at 0ft and at 70ft. Please see the Note On Corrected Values as well for further information.NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- Mach Hi Corrected Commanded Ne Table: The commanded N2 (corrected) vs. throttle table when at HI Mach. This table of values uses the delta pressure ratio and the throttle position to calculate a maximum mach which is then used to generate the corrected N2 value. Note that we use the inverse of delta pressure ratio (Psl/P) so that values are in increasing order, and we give values at 0ft and at 70ft. Please see the Note On Corrected Values as well for further information.NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- Use Corrected N2 From FF Table: Define whether or not to use the Corrected N2 From FF Table. When checked, this table will be used. When unchecked, the N2 will be calculated based on a formula using High N2, Low Idle N2, High Fuel Flow and Idle Fuel Flow. Please see the Note On Corrected Values as well for further information.NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- Corrected N2 From FF Table: This table describes the relationship between the corrected fuel flow and N2. In the flight model calculations the input for the interpolation is the corrected FF / static thrust scalar in order to "scale" the input for the engine power. Note that this table depends on the Use Corrected N2 From FF Table parameter, and if that parameter is checked then this table is required. Please see the Note On Corrected Values as well for further information.NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- N1 And Mach On Thrust Table: This table uses the corrected N1 and mach as input and outputs a multiplier that will be applied - using bi-linear interpolation - to the gross thrust. Please see the Note On Corrected Values as well for further information.NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- Corrected Airflow Table: This table is used along with the Inlet Area value in the computation of Ram Drag or the jet turbine. Input is the corrected N1 and Mach, and output will be the airflow (this is a momentum expressed in Slug sqft). Please see the Note On Corrected Values as well for further information.

NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- EPR Max: The maximum EPR for the engine, as a percentage. The engine EPR is calculated with this formula:

EPR = EprMax * N2AndMachToEprTable * DeltaPressRatio

NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- EPR TC: The EPR time constant, in seconds, used to define at which speed the effective EPR will reach the target EPR based on the current situation. The time constant formula works like this:

CurrentEPR = (EPR - CurrentEPR) /times DeltaTime /times EPRTimeConst

NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- Oil Temp Tuning Constant: Oil temperature tuning constant, which is a global scalar of the oil temperature. This is the oil temperature calculation formula:

OilTemp = OilTempTuningConstant * (OilTempHeatingConstant * N1OilTempTable)

NOTE: TheN1OilTempTableis not exposed and defined directly in the code.

- Oil Temp Heating Constant: Maximum oil temperature, in Rankine. This is the oil temperature calculation formula:

OilTemp = OilTempTuningConstant * (OilTempHeatingConstant * N1OilTempTable)

NOTE: TheN1OilTempTableis not exposed and defined directly in the code.

- Oil Temp Time Constant: Oil temperature time constant, in seconds, which defines at which speed the effective oil temperature will reach the target oil temperature based on the current situation. The time constant formula works like this:

CurrentOilTemp = (OilTemp - CurrentOilTemp) * DeltaTime * OilTempTC\)

- Oil Press Tuning Constant: Oil pressure tuning constant which is an intermediate scalar of oil pressure. This is the oil pressure formula:

OilPress = OilPressTuningConstant /times OilPressMax * N1ToOilPressureTable + PropLeverPosToOilPressureDeltaTable - OilLeakage

NOTE: This formula will only use the Prop Lever Pos To Oil Pressure Delta parameter if the Engine Type is set to "TurboProp" and feathering is available.

- Oil Press Max: The maximum permitted oil pressure in psf. This is the oil pressure formula:

OilPress = OilPressTuningConstant /times OilPressMax * N1ToOilPressureTable + PropLeverPosToOilPressureDeltaTable - OilLeakage

NOTE: This formula will only use the Prop Lever Pos To Oil Pressure Delta parameter if the Engine Type is set to "TurboProp" and feathering is available.

- Oil Press TC: Oil pressure time constant, in seconds, which defines the speed at which the effective oil pressure will reach the target oil pressure based on the current situation. The time constant formula works like this:

CurrentOilPress = (OilPress - CurrentOilPress) * DeltaTime * OilPressTC

- ITT Peak Temperature: Set the ITT peak temperature value, in Rankine. For jet engines the ITT formula is the following:

ITT = itt_tuning_constant * (itt_peak_temperature * (FuelFlow * (fuel_flow_max_itt_factor - fuel_flow_min_itt_factor) + fuel_flow_min_itt_factor) - ITTCooling)

For turboprop engines, the ITT formula is:ITT = itt_tuning_constant * (itt_peak_temperature * (FuelFlow * (FuelFlowITTMax - FuelFlowITTMin) + FuelFlowITTMin) - ITTCooling)

NOTE:FuelFlowITTMinandFuelFlowITTMaxare defined directly in code as 0.65 and 0.8 respectively. Also,ITTCoolingis an abstraction of the calculations made by the simulation, based on airflow, which contribute to cooling the engine.

- ITT TC: Set the ITT time constant, in seconds, used to define the speed at which the effective ITT will reach the target ITT based on the current situation. The time constant formula works like this:

CurrentEGT = (ITT - CurrentITT) * DeltaTime * itt_tc

Note that by default the final value (in degrees Rankine per second) is clamped between -50 and 50. However you can use the ITT Max Correction parameter to change this.

- ITT Tuning Constant: Set the ITT tuning constant which is the Global scalar of the ITT temperature. For jet engines the ITT formula is the following:

ITT = itt_tuning_constant * (itt_peak_temperature * (FuelFlow * (fuel_flow_max_itt_factor - fuel_flow_min_itt_factor) + fuel_flow_min_itt_factor) - ITTCooling)

For turboprop engines, the ITT formula is:ITT = itt_tuning_constant * (itt_peak_temperature * (FuelFlow * (FuelFlowITTMax - FuelFlowITTMin) + FuelFlowITTMin) - ITTCooling)

NOTE:FuelFlowITTMinandFuelFlowITTMaxare not exposed and are hard-coded.

- ITT Max Correction: This parameter controls the maximum ITT change in degrees Rankine per second. Set this to a higher value if you have a large ITT TC and want a faster change of the ITT value to match.

- Fuel Flow Min ITT Factor: Scalar of the ITT temperature at minimum fuel flow. The ITT formula is the following:

ITT = itt_tuning_constant * (itt_peak_temperature * (FuelFlow * (fuel_flow_max_itt_factor - fuel_flow_min_itt_factor) + fuel_flow_min_itt_factor) - ITTCooling)

NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet". Also,ITTCoolingis an abstraction of the calculations made by the simulation, based on airflow, which contribute to cooling the engine.

- Fuel Flow Max ITT Factor: Scalar of the ITT temperature at maximum fuel flow. The ITT formula is the following:

ITT = itt_tuning_constant * (itt_peak_temperature * (FuelFlow * (fuel_flow_max_itt_factor - fuel_flow_min_itt_factor) + fuel_flow_min_itt_factor) - ITTCooling)

NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet". Also,ITTCoolingis an abstraction of the calculations made by the simulation, based on airflow, which contribute to cooling the engine.

- N1 Cooling Factor: Scalar of the ITT temperature cooling.NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- EGT Peak Temperature: The EGT peak temperature, in Rankine (typically calculated as °F + 460). The EGT temperature is calculated by remapping the ITT temperature to the EGT Peak Temperature and correcting it to the temperature ratios.

- EGT TC: The EGT time constant, in seconds, used to define the speed at which the effective EGT will reach the target EGT based on the current situation. The time constant formula works like this:

CurrentEGT = (EGT - CurrentEGT) * DeltaTime * egt_tc

- Fuel Press Tuning Constant: Fuel pressure tuning constant, which is the global scalar of the fuel pressure. This is the fuel pressure calculation formula:

FuelPress = fuel_press_tuning_constant * fuel_press_max * rpm_to_fuel_pressure_table

NOTE: This is for legacy Fuel flow only.

- Fuel Press Max: Maximum permitted fuel pressure, in psf. This is the fuel pressure calculation formula:

FuelPress = fuel_press_tuning_constant * fuel_press_max * rpm_to_fuel_pressure_table

NOTE: This is for legacy Fuel flow only.

- Fuel Press TC: Fuel pressure time constant, in seconds.

NOTE: This is for legacy Fuel flow only.

- Variable Inlet: Sets whether the variable inlet is activated (checked) or not (unchecked). If activated, the inlet Mach will be limited to 0.5. If deactivated, the inlet Mach will be limited to 1.0.

- Primary Nozzle Available: Sets whether the primary nozzle is activated (checked) or not (unchecked). The primary nozzle formula works like this:

PrimaryNozzle = primary_nozzle_n_mach_to_nozzle_pos + primary_nozzle_afterburner_offset * primary_nozzle_available

- Primary Nozzle Afterburner Offset: Sets the primary afterburner nozzle offset, in ft. The primary nozzle formula works like this:

PrimaryNozzle = primary_nozzle_n_mach_to_nozzle_pos + primary_nozzle_afterburner_offset * primary_nozzle_available

- Primary Nozzle N1 Mach To Nozzle Pos: This table takes the N1 and Mach as input values, and outputs the nozzle position as a Percent Over 100. The primary nozzle formula works like this:

PrimaryNozzle = primary_nozzle_n1_mach_to_nozzle_pos + primary_nozzle_afterburner_offset * primary_nozzle_available

- JET Density On FF Table: This table allows you to tune the fuel flow to the engine depending on the ambient air density. The table should have values that roughly correspond to the following altitudes: 60k feet, 40k feet, 35k feet, 30k feet, 25k feet, 20k feet, 15k feet, 10k feet, 5k feet, 0k feet.NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet". For TurboProp, use the Density On FF Table parameter.

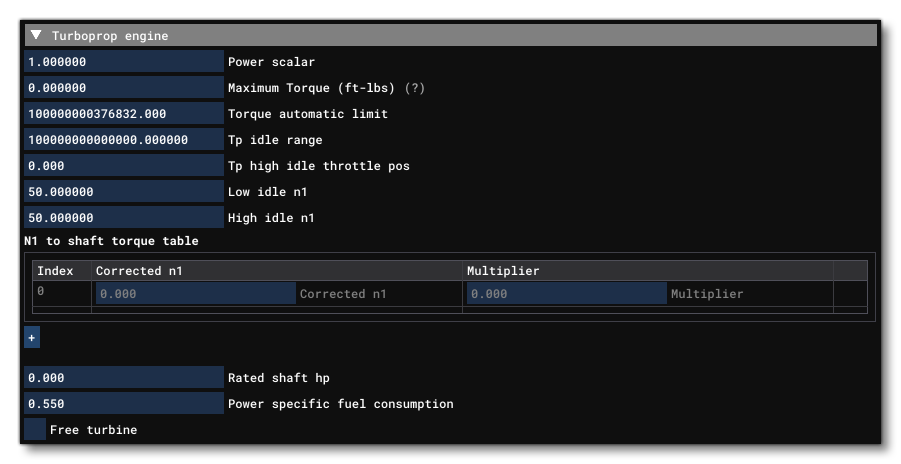

- Density On Torque Table: This table allows you to tune the torque that the engine will produce depending on the ambient air density. The table should have values that roughly correspond to the following altitudes: 60k feet, 40k feet, 35k feet, 30k feet, 25k feet, 20k feet, 15k feet, 10k feet, 5k feet, 0k feet.

Torque = min(torque_automatic_limit, maximum_torque * n1_to_shaft_torque_table * density_on_torque_table * RPM_on_TP_torque_table)

NOTE: This parameter is for TURBOPROP engines only and will only be available if the Engine Type is set to "TurboProp".

- Density On FF Table: This table allows you to tune the fuel flow to the engine depending on the ambient air density. This affects the final fuel consumption fuel flow only, not the fuel input and engine performance calculations. Therefore it can be used as a density dependent engine thrust specific fuel consumption scalar. The table should have values that roughly correspond to the following altitudes: 60k feet, 40k feet, 35k feet, 30k feet, 25k feet, 20k feet, 15k feet, 10k feet, 5k feet, 0k feet.NOTE: This parameter is for TURBOPROP engines only and will only be available if the Engine Type is set to "TurboProp". For jets, use the JET Density On FF Table parameter.

- RPM On TP Torque Table: This table allows you to tune the shaft torque generated by the engine based on the propeller RPM.NOTE: This parameter is for TURBOPROP engines only and will only be available if the Engine Type is set to "TurboProp".

- Starter N1 Max: The percentage of maximum RPM that is reached using only the starter.

- Starter N1 Rate: The rate at which the starter N1 increases.

- Ignition Auto Type: This value specifies how auto ignition is handled when enabled. This is defined by checking one or more of the following checkboxes:

- Min Condition Lever For Combustion: The minimum position of the condition lever to obtain a combustion, expressed as a Percent Over 100.

- Min N1 For Combustion: The minimum N1 to sustain a combustion without the starter being active.

- Min N2 For Combustion: The minimum N2 to sustain a combustion without the starter being active.NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- Min N1 For Starter Cutoff: The minimum N1 at which the starter will be deactivated and the engine should continue to run on its own. You'll notice that the default value for this is 200 - which is an unreachable value -so that the starter never cuts off automatically.

- Min N2 For Starter Cutoff: The minimum N2 at which the starter will be deactivated and the engine should continue to run on its own. You'll notice that the default value for this is 200 - which is an unreachable value -so that the starter never cuts off automatically.NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- N1 Normal TC: The changing N1 acceleration factor during normal use of the engine.

- N1 Start Max Rate: The limiting N1 acceleration factor during starter use.

- N1 Start Combustion Max Rate: The limiting N1 acceleration factor during startup when combustion has started.

- N2 Raw Starter: The percentage given by the starter that N2 will try to reach. Note that this value will only be considered if the Starter Type is not of the "bleed air" type.

NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- N2 Starter Rate: The rate at which N2 will reach the N2 Raw Starter percentage. Note that this value will only be considered if the Starter Type is not of the "bleed air" type.

NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- N2 Starter Max Rate: This can be used to set the maximum percentage per second rate that N2 can reach under Low Idle N2 (when starting the turbine usually). This is useful to cap values coming from existing Bleed Air On N2 TC or N2 From Bleed Air PSI Table.

NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- Idle Fuel Flow: The idle fuel flow in lbs per hour. Note that if you are using a turboprop condition lever (see the SimVar

TURB_ENG_CONDITION_LEVER_POSITIONfor more information), then this needs to be set to the same value as Idle High Fuel Flow.

- Idle High Fuel Flow: The idle high fuel flow in lbs per hour. Note that if you are using a turboprop condition lever (see the SimVar

TURB_ENG_CONDITION_LEVER_POSITIONfor more information), then this needs to be set to the same value as Idle Fuel Flow.

- Low Idle N1: Set the low idle value for N1, as a percent between 0 and 100, where 100 is the maximum rated N1. Note that if you are using a turboprop condition lever (see the SimVar

TURB_ENG_CONDITION_LEVER_POSITIONfor more information), then this needs to be set correctly.

- Low Idle N2: Set the low idle value for N2, as a percent between 0 and 100, where 100 is the maximum rated N2.NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- High N1: Set the high value for N1, as a percent between 0 and 100, where 100 is the maximum rated N1.

- High N2: Set the high value for N2, as a percent between 0 and 100, where 100 is the maximum rated N2.

NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- High Idle N1: Set the high idle value for N1, as a percent between 0 and 100, where 100 is the maximum rated N1. Note that if you are using a turboprop condition lever (see the SimVar

TURB_ENG_CONDITION_LEVER_POSITIONfor more information), then this needs to be set correctly.

- High Fuel Flow: The high fuel flow in lbs per hour. This is the fuel flow you get when N1 and N2 are operating at High N1 and High N2 speeds.

- Min N2 For Fuel Flow: Sets the minimum percentage N2 for fuel to flow.

NOTE: This parameter is for JET engines only and will only be available if the Engine Type is set to "Jet".

- Mach Influence On N1: This is a scalar value that is applied to the inlet mach to create the corrected N1 value using the following formula:

raw_corrected_N1 += mach_influence_on_n1 * inletMach

- Fuel Flow Max: This is the maximum fuel flow available under any circumstances. This value is used to clamp the computed corrected fuel flow value.

- Fuel Flow Controller P: The turbine flow controller P value. Part of the full PID definition for the turbine engine that controls the current fuel flow to reach a target fuel flow value. This parameter is explored in more detail here: PID Parameters.

- Fuel Flow Controller I: The turbine flow controller I value. Part of the full PID definition for the turbine engine that controls the current fuel flow to reach a target fuel flow value. This parameter is explored in more detail here: PID Parameters.

- Fuel Flow Controller D: The turbine flow controller D value. Part of the full PID definition for the turbine engine that controls the current fuel flow to reach a target fuel flow value. This parameter is explored in more detail here: PID Parameters.

- Fuel Flow Controller Iboundary: The turbine flow controller I boundary. This parameter is explored in more detail here: PID Parameters.

- Fuel Flow Controller Dboundary: The turbine flow controller D boundary. This parameter is explored in more detail here: PID Parameters.

- Max Torque Protection: The value of the torque triggering a protection by automatically limiting the fuelflow. A value of 0 is no protection.

- Max N1 Protection: The value at which the N1 triggers a protection by automatically limiting the fuelflow. A value of 0 is no protection.

- Max N2 Protection: The value at which the N2 triggers a protection by automatically limiting the fuelflow. A value of 0 is no protection.

- Max EGT Protection: The value at which the EGT triggers a protection by automatically limiting the fuelflow. A value of 0 is no protection.

- N2 From Bleed Air PSI Table: Table which contains the N2 generated depending on the pressure of the bleed air from the APU (in psi).

- Bleed Air On N2 TC: Time constant which contains the speed at which the bleed air pressure affects the N2 of the turbine, in seconds.

- N1 To Oil Pressure Table: The percentage N1 to percentage max oil pressure, as a table. This is the oil pressure formula:

OilPress = oil_press_tuning_constant * oil_press_max * N1_to_oil_pressure_table + prop_lever_pos_to_oil_pressure_delta_table - OilLeakage