TESTING THE AIRCRAFT

This page is all about testing the aircraft, and covers some of the things you should be checking and tweaking to refine the aircraft flight model before going on to add anything further to the final package. On this page we'll be referring to information from the various debug windows, in particular the Debug Aircraft Tracking window, and also from the POH for the aircraft, so you should have that at hand too.

Takeoff Distance

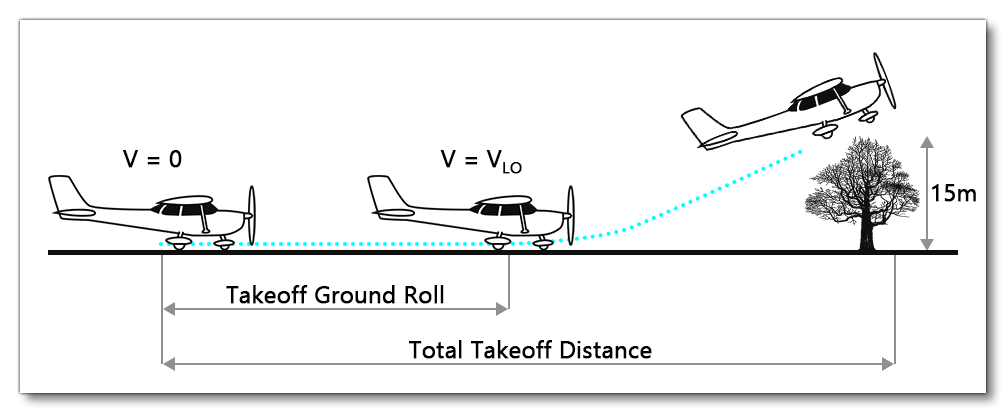

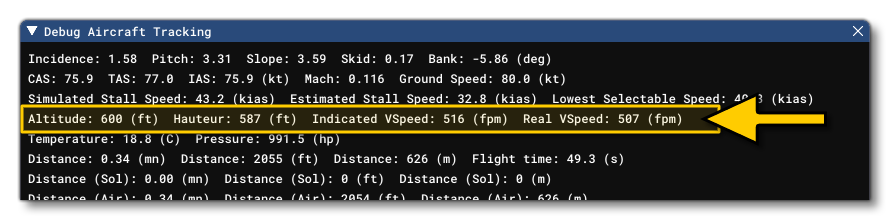

To test the takeoff distance, you need to start a flight on the runway and then look at the distance values in the Debug Aircraft Tracking window and compare them to the POH data as you perform the takeoff:

![]()

Note that if the aircraft ground roll distance is not specified, then you can use the total takeoff distance to calculate it:

The total takeoff distance is comprised of the combined ground roll distance and the air distance to clear a 50ft (15m) obstacle. Checking these values against the expected values can help you to adjust the throttle, engine, and other flight model parameters to get a correct takeoff.

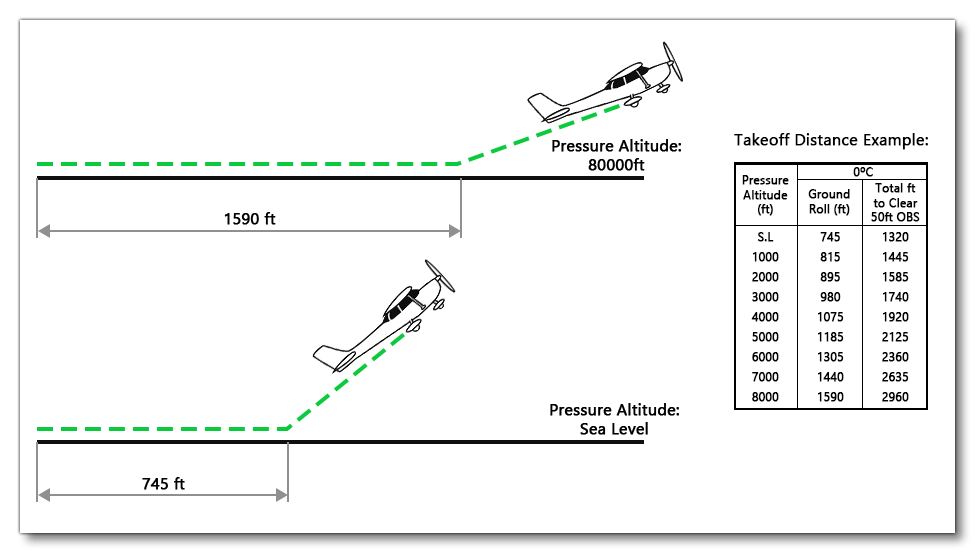

Another thing to take into consideration when tuning the aircraft, is the pressure altitude. This has a huge impact on the takeoff distance, so make sure to test and validate at Sea Level, and at the Clear Sky preset (ISA parameters):

It is also important to respect the same takeoff technique recorded in the POH - flaps level, speeds, brake, and throttle - to validate the data in the same conditions.

Takeoff Trim

You will also want to validate and adjust - if required - the takeoff trim. For that you should do the following:

- Apply full throttle and let the aircraft accelerate.

- Look at what speed the aircraft starts to rotate by itself.

- Rotating should not happen before - or exactly at - the POH rotation speed because at those speeds the rotation should need a clear pilot input

- Rotation should not happen too late either, otherwise the input to make the rotation and maintain the initial climb will be too much.

NOTE: "Rotation Speed" is the initial speed at which the longitudinal axis of the aircraft is "rotated" about its lateral axis from a horizontal orientation in order to increase the angle of attack of the wing.

In general, you can make a guesstimate speed of about 30% above published rotation speed as the expected behavior for your aircraft.

Climb Performances

There are two primary reasons to evaluate climb performance:

- Aircraft must climb over obstacles to avoid hitting them.

- Climbing to higher altitudes can provide better weather, fuel economy, and other benefits.

Maximum Angle of Climb (AOC), obtained at \({V_X}\), may provide climb performance to ensure an aircraft will clear obstacles. Maximum Rate of Climb (ROC), obtained at \({V_Y}\), provides climb performance to achieve the greatest altitude gain over time. Maximum ROC may not be sufficient to avoid obstacles in some situations, while maximum AOC may be sufficient to avoid the same obstacles. We have more or less covered AOC in the section above, so now let's look at getting the correct ROC:

- Find the Maximum Rate of Climb in the POH (usually under Section 5, Performance)

- Climb to the desired kias and trim the aircraft to maintain that speed, then let it stabilize.

- Once stabilized - and no yoke input is required - check the Vertical Speed.

NOTE: When looking in the POH, don't forget that ISA temperature is 15°

The real method used to derived the POH values is to trim the aircraft, start a stopwatch, and then plot the altitude gained every minute. Done several times in different weather conditions, an average is made out of the results.

Max Speed

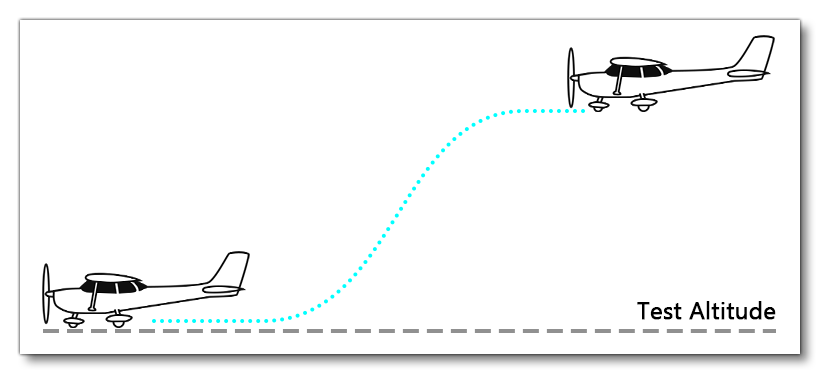

The most time efficient way to test and calibrate the Max Speed - and see the effect of drag at the same time - is to fly at full throttle above the test altitude and then dive to exceed the max speed and level off at the test altitude, while keeping the full throttle.

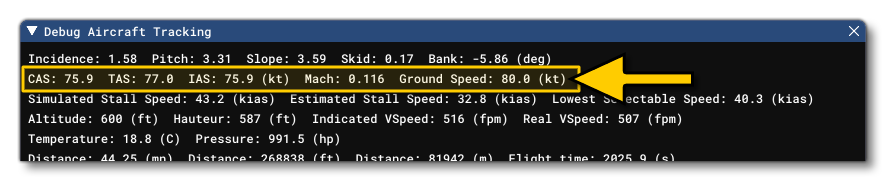

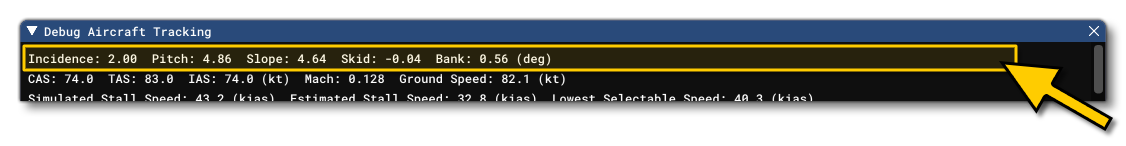

When doing this, drag will then come into effect and slow down the aircraft to the max speed achievable at full throttle. You can check the Debug Aircraft Tracking for the TAS and IAS airspeeds:

Note that the higher the altitude, the higher the difference will be between IAS and TAS.

Fuel Consumption

Another important thing to check and calibrate is the fuel consumption for the aircraft. The egenral way that you would do this is as follows:

- Find the fuel consumption for a specific configuration in the POH (usually under Section 5, Performance).

- Now fly the aircraft using the mentioned configuration

- Lean the fuel/air mixture by reducing the mixture gradually until the engine runs a little rough. You may see a slight Increase in rpm before the engine starts to roughen.

- Slowly enrich the mixture until the engine smooths out. This is what's known as a "best economy" setting.

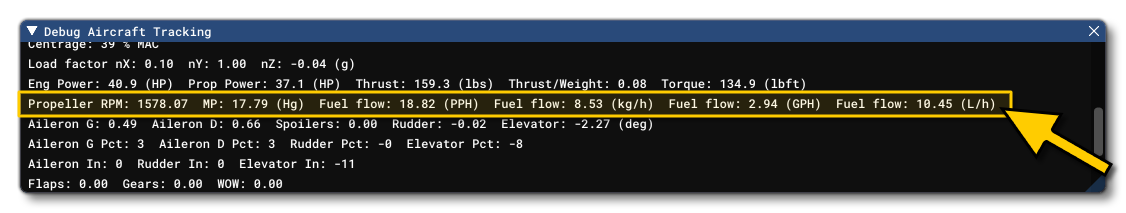

- Look at the fuel flow in the Debug Aircraft Tracking.

NOTE: Using the same configuration you can also check and calibrate the cruise speed in TAS.

Stability

For testing and calibrating the aircraft stability, you will need to refer to the aircraft certification requirements (see here for more information).

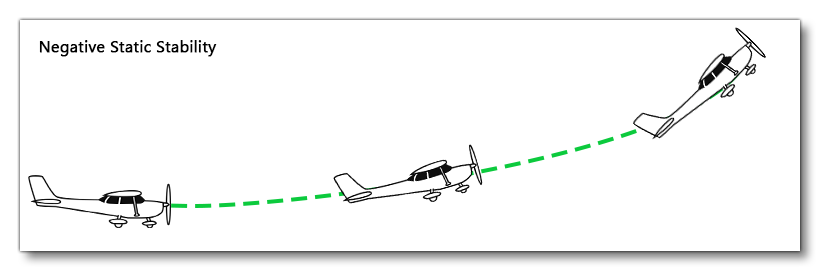

Static Stability

Static stability describes the initial tendency with which an aircraft will react when disturbed. There are three kinds of static stability:

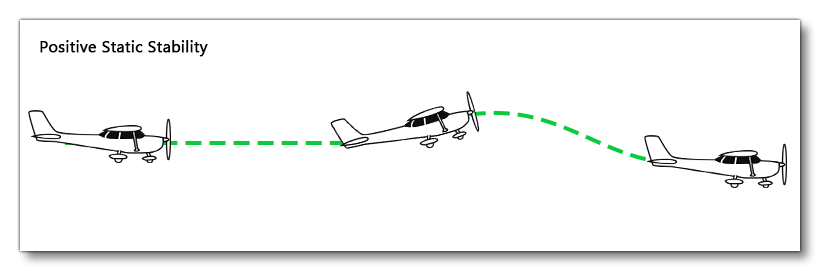

- Positive: An aircraft that has positive static stability tends to return to its original attitude when it's disturbed. Let's say you're flying an aircraft, you hit some turbulence, and the nose pitches up. Immediately after that happens, the nose lowers and returns to its original attitude.

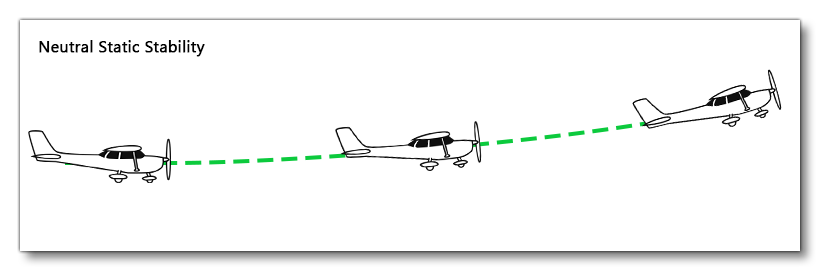

- Neutral: An aircraft that has neutral static stability tends to stay in its new attitude when it's disturbed. For example, if you hit turbulence and your nose pitches up 5 degrees, and then immediately after that it stays at 5 degrees nose up, your airplane has neutral static stability.

- Negative: Finally, an aircraft that has negative static stability tends to continue moving away from its original attitude when it's disturbed. For example, if you hit turbulence and your nose pitches up, and then immediately continues pitching up, you're airplane has negative static stability. For most aircraft, this is a very undesirable thing.

To test the static stability, start trimmed at cruise configuration and give a short but firm pitch input to deviate away from the trimmed airspeed (slower or faster) and observe the initial response of the aircraft and see whethr it's Positive, Neutral, or Negative. You would then go ahead adjust the wing surface parameters and other things wiell affect the flight model to get it to show the desired behavior.

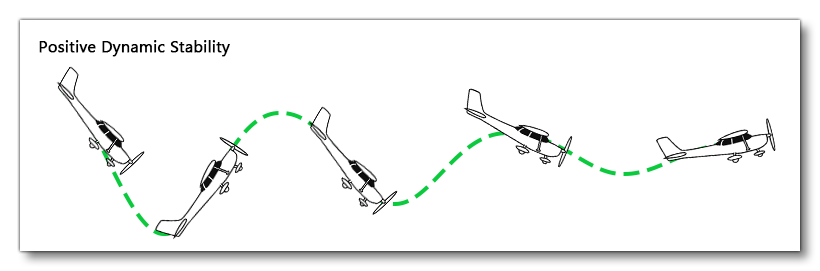

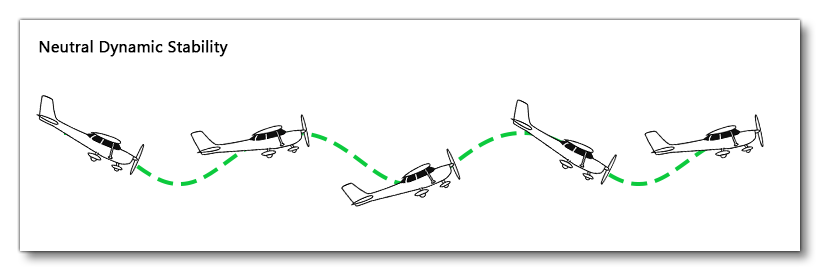

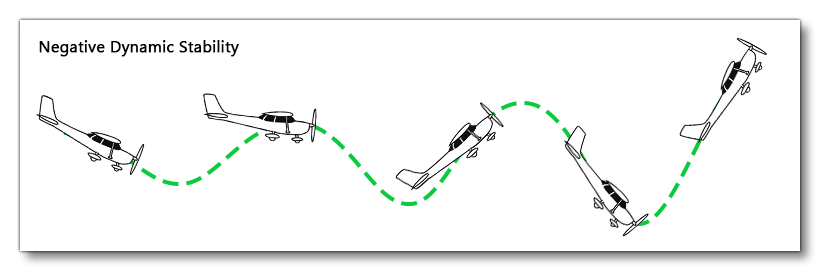

Dynamic Stability

Dynamic stability describes how an aircraft will respond over time to a disturbance. LIke with Static Stability, Dynamic stability comes in three types as well:

- Positive: Aircraft with positive dynamic stability have oscillations that dampen out over time. When the aircraft is trimmed for level flight and you pull back on the yoke and then let go, the nose will immediately start pitching down. Depending on how much you pitched up initially, the nose will pitch down slightly nose low, and then, over time, pitch nose up again, but less than your initial control input. Over time, the pitching will stop, and your aircraft will be back to its original attitude.

- Neutral: Aircraft with neutral dynamic stability have oscillations that never dampen out. As you can see in the diagram below, if you pitch up a trimmed, neutrally dynamic stable aircraft, it will pitch nose low, then nose high again, and the oscillations will continue, in theory, forever.

- Negative: Aircraft with negative dynamic stability have oscillations that get worse over time. The diagram below shows an exaggerated example of this effect. Over time, the pitch oscillations will get more and more amplified.

When it comes to testing the dynamic stability of the aircraft, you will need to use the following basic flight dynamic modes:

- Short Period Ocillations: The short-period mode is an - usually heavily damped - oscillation with a period of only a few seconds. The motion is a rapid pitching of the aircraft about the center of gravity, essentially an AoA variation. The time to damp the amplitude to one-half of its value is usually on the order of 1 second. Ability to quickly self damp when the stick is briefly displaced is one of the many criteria for general aircraft certification.

- Phugoid: This longer period mode is the one in which there is a large amplitude variation of airspeed, pitch angle, and altitude, but almost no AoA variation. The phugoid oscillation is a slow interchange of velocity and height about an equilibrium point as the aircraft attempts to re-establish the level-flight condition from which it had been disturbed. The motion is so slow that the effects of inertia forces and damping forces are very low. Although the damping is very weak, the period is so long that the pilot usually corrects for this motion without being aware that the oscillation even exists. Typically the period is 20–60 seconds, which you should try and measure as well as determine the frequency and damping ratio.

- Dutch roll: This is a combined roll and yaw motion to the right, followed by a recovery towards the equilibrium condition, then an overshooting of this condition and a yaw and roll to the left, then back past the equilibrium attitude, and so on. Damping is increased by large directional stability and small dihedral and decreased by small directional stability and large dihedral. The period is usually on the order of 3–15 seconds, but it can vary from a few seconds for light aircraft to a minute or more for airliners. To test this, you will need to evaluate frequency, ratio, and the nature of the damping and damping ratio.

- Spiral Divergence: Spiraling is inherent in any aircraft. Most aircraft trimmed for straight-and-level flight, if flown stick-fixed, will eventually develop a tightening spiral-dive, and if a spiral dive is entered unintentionally, the result can be fatal. This needs to be tested and changes will need to be made to the aileron, rudder, and other side areas aft of the plane's centre of gravity to ensure the behavior matches that given for certification requirements. To test this put the aircraft in a 30° bank angle and let the aircraft lose altitude. Measure the time to double bank angle. It should not double in less than 20 seconds.

Static Lateral Directional Stability

Lateral stability and control relates to an aircraft's rolling motion, while directional stability and control relates to an aircraft's yawing motion. In this section we'll give some tips on how to test and calibrate both the lateral and directional static stability of the aircraft at the same time.

For testing we'll be using the Steady Heading Sideslip (SHSS) maneuver. This is a calibration method where the aircraft is simultaneously banked and yawed while maintaining a constant heading:

- The maneuver starts with the aircraft trimmed in straight and level flight using cruise and approach conditions (speed and flaps), with a ß at 0°. During this time the wind velocity is calculated and assumed to be constant for the duration of the maneuver.

- A constant force should then be applied on the rudder pedal. The aircraft will yaw in response to the rudder input and you should bank the aircraft in the opposite direction of the yaw in order to stabilize it at a constant heading.

- The sideslip and bank angle are then incrementally increased until reaching the maximum attainable angle of sideslip. You should record ß max (the Skid angle in the debug window) at full rudder.

- Finally you should repeated the maneuver in the opposite direction, returning to trim conditions.

Note that this maneuver should be done at both cruise speed and at approach speed. Also note that in a Steady Heading Side Slip maneuver on a GA aircraft, you will usually run out of rudder first (which is when more aileron than rudder is available). The amount of rudder available is the real crosswind limitation of the aircraft.

Roll Rate

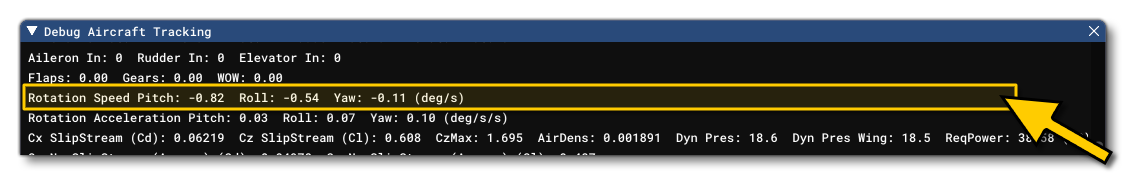

The roll rate, expressed in degrees per second, is the rate at which an aircraft can change its roll attitude. To test the Roll rate, start in cruise conditions and then apply a full aileron input, while checking the debug window Roll Value:

Keep in mind that with altitude the air density will decrease, so the roll rate will be higher at 20,000 ft than at 5,000 ft. A real technique that can be used to test the roll rate is to measure the time to perform the change from a 30° bank angle on one side to a 30° bank angle on the other side (so, a 60° roll in total).

Keep in mind that with altitude the air density will decrease, so the roll rate will be higher at 20,000 ft than at 5,000 ft. A real technique that can be used to test the roll rate is to measure the time to perform the change from a 30° bank angle on one side to a 30° bank angle on the other side (so, a 60° roll in total).

Flaps

For flaps in general, we recommend the following process to get the correct configuration of values:

- Set the stall AoA in the lift table to the highest stall AoA across all flap settings.

- Set the stall lift in the lift table to get the stall speed and recommended speed AoA with clean flap setting right.

- Set the flap lift coefficient to get the correct AoA at full flap stall speed.

- Set the flap incidence coefficient to fine tune the AoA at recommended speed at flap levels.

Stall

A stall occurs when the angle of attack of an aerofoil exceeds the value which creates maximum lift as a consequence of airflow across it. This angle varies very little in response to the cross section of the (clean) aerofoil and is typically around 15°. This can be defined as one of the following:

- Uncontrollable downward pitching motion

- Downward pitching motion that results from the activation of a device (for example stick pusher)

- The control reaches the stop (Full aft stick)

To test this, you should be at maximum weight, and at idle power, then do the following:

- Trim the aircraft at 1.4 predicted stall speed.

- Power IDLE, pitch up to reduce the speed with a bleed rate of 1 ktas/s until stall occurs.

- Observe the buffet, break or aft stick.

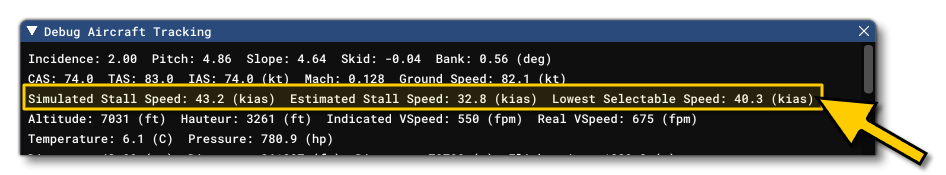

The elevator max angle scalar can be fine tuned to get the desired stall behavior, based on the simulated stall speed in the Debug Aircraft Tracking window and comparing it to the POH data.

You should repeat the test in landing configuration (full flaps) to see the effect of the lift added by the flaps.

Controls Elasticity

At this point you will want to calibrate and tweak the control elasticity. You want to see if you have enough control at max speed (\({V_{ne}}\)) and maneuver speed (\({V_a}\)) to reach the maximum G's, or just a bit more. To test the control elasticity, you should do the following:

Fly the aircraft and dive to reach \({V_{ne}}\).

See if the dynamic pressure matches the dynamic pressure set in the elasticity table.

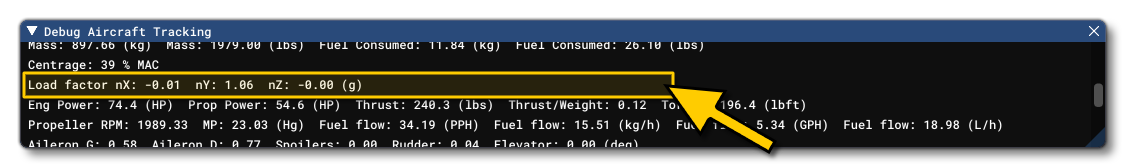

Apply full aft stick and look at the max "nY" G's in the Debug Aircraft Tracking.

Compare this value to the aircraft data and repeat the procedure at maneuver speed (\({V_a}\)).

Compare this value to the aircraft data and repeat the procedure at maneuver speed (\({V_a}\)).

Approach And Landing

If all the tests above are done and everything is looking good, almost all that remains to test is basically the effect of flaps drag. This can be tested as follows:

- Trim the aircraft at approach speed (1.3 \({V_{S0}}\)) at full flaps and idle power.

- Look at the Vertical Speed.

- Add power to maintain a 500 ft/min descent rate.

- Look at how much power is required.

The results can then be compared to the data computed in the Plane Performance Spreadsheet.

Aircraft Damage

While not exactly related to performance, the aircraft behaviour when over-stressed and suffering damage is still an important part of creating a good flight model. As such, we have compiled a list of the ares that you should pay attention to and the factors that will cause a crash when the pilot over-stresses the aircraft.

Note that when testing these things, you will need to make sure you have all assistances turned off and that the Disable Crashes option of the Devmode is un-checked.

Flaps Damage and Blowout

Flaps damage is only used to trigger the pilot assistance warning when the aircraft speed reaches (or is higher than) the value given in the damaging-speed parameter of the [FLAPS.N] section of the flight-model.cfg. However, there will be no efficiency degradation to the aircraft when this happens.

When the aircraft speed goes high enough, it can trigger flaps blowout. Be aware though, that this will not happen at the speed given using the blowout-speed parameter of the [FLAPS.N] section of the flight-model.cfg. Instead, this value is used to get the dynamic pressure using the following formula:

$$\textrm{dynamic\_pressure} = (0.5 \times {sea\_level\_density} \times speed^{2})$$

When this level of pressure is reached an assistance warning is triggered, and then the actual blowout will only occur when the dynamic pressure reaches two times the calculated pressure threshold.

Overspeed Damage

The aircraft will suffer an overspeed crash when it is flown above the \(V_{ne}\)$$ for more than 6 seconds.

Overstress Damage

The overstress crash will occur when you fly beyond the negative or positive G limit for more than 1 second. This G limit is computed as an interpolation of the following parameters from the [AIRPLANE_GEOMETRY] section of the flight-model.cfg file:

positive_g_limit_flaps_uppositive_g_limit_flaps_downnegative_g_limit_flaps_upnegative_g_limit_flaps_down

Note that the interpolation will be based on flaps position.

Landing Gear Damage

Landing gear will be damaged if the aircraft goes above the Airspeed Dam. speed given in the [Point.N] section for [CONTACT_POINTS] (in the flight-model.cfg). If the landing gear is flagged as damaged, this will not trigger a crash. However, it will prevent the landing gear from extending or retracting correctly, which means that only retractable landing gear will be affected currently.